High Speed Steel

Categorized with the prefixes ‘T’ and ‘M’, our high speed steel is designed to retain their strength and hardness while working at temperatures up to 760°C. The ‘M’ type high speed steels were designed specifically to reduce the need for tungsten and chromium.

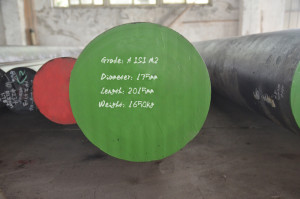

M2

M2 Steel is a general purpose molybdenum steel.

M35

M35 HSS is similar with M2 speed steel but with added 5% cobalt to increase hot hardness.

M42

The M42 Steel is known for its balanced combination of abrasion resistance, toughness and good red hardness.M42 is a tungsten-molybdenum high speed steels.

T1

The T1 is known for its balanced combination of abrasion resistance, high toughness, high hardness (can reached 62~66Hrc) and good red hardness (can work in Max 620 °C, Advice work below 600 °C) tungsten-molybdenum high speed tool steel.

T5

The T5 Steel is known for High Tungsten-cobalt HSS steel. Its balanced combination of abrasion resistance, high toughness, high hardness (can reached 62~70Hrc) and high red hardness.

T15

AISI T15 High Speed Steel is air or oil hardening tool steel that has exceptional wear resistance. It resists softening at high operating temperatures.