1.3243 High Speed Steel

OTAI SPECIAL STEEL is 1.3243 High Speed Steel stockholders and suppliers from china. more 16 years experience in 1.3243 High Speed Steel round bar, flat bar and plate supply.

1.3243 High Speed Stee is a high quality tool steel, It belong to the high quality high carbon alloy tool steel. 1.3243 steel equivalent with 2723,SKH55,S6-5-2-5 Steel.

1.3243 tool steel properties as below:

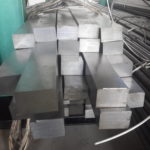

Form of Supply

1.3243 High Speed Steel, we can supply the round bar, steel flat bar, plate, hexagonal steel bar and steel square block. 1.3243 steel Round bar can be sawn to your required lengths as one offs or multiple cut pieces. 1.3243 steel Rectangular pieces can be sawn from flat bar or plate to your specific sizes. Ground tool steel bar can be supplied, providing a quality precision finished bar to tight tolerances.

- Round

- sheet

- Square

- Plate

Chemical composition

| C(%) | 0.87~0.95 | Si(%) | ≤0.450 | W(%) | 5.90~6.70 | P(%) | ≤0.030 |

| S(%) | ≤0.030 | Cr(%) | 3.80~4.50 | Mo (%) | 4.70~5.20 | V(%) | 1.7~2.10 |

Mechanical Properties

The mechanical properties of 1.3243 High Speed Steels are outlined in the following table.

| Rp0.2 (MPa) | Tensile Rm (MPa) |

Impact KV/Ku (J) |

Elongation A (%) |

Reduction in cross section on fracture Z (%) |

As-Heat-Treated Condition | Brinell hardness (HBW) |

|---|---|---|---|---|---|---|

| 267 (≥) | 727 (≥) | 11 | 41 | 13 | Solution and Aging, Annealing, Ausaging, Q+T,etc | 423 |

Heat Treatment

1.Soft-annealing 850°C – 900°C / 1560°F – 1650°F, slow cooling 10°C / 18°F/h to 700°C / 1290°F, hardness max 260 Brinell.

2.Stress relieving 600°C – 700°C / 1120°F – 1290°F, approx. 2 hours at temperature, slow cooling to 500°C / 930°F.

3.Hardening with preheating in two steps 450°C – 500°C / 840°F – 930°F,850°C – 900°C / 1560°F – 1650°F and austenitizing at

1050°C – 1220°C / 1920°F – 2230°F. Quenching to about 550°C / 1022°F then cool in air to hand warm

4.Tempering at 560°C / 1040°F or higher 2 times for at least 1 hour at full temperature is recommended.

Applications

| 1.Cutting tools such as, broaches, taps, milling, reamers, hobs, shapers cutters, saws etc. In terms of performance; | |||||

| 2.To be used in cutting conditions where demands for hot hardness are of importance; | |||||

| 3.Suitable for cold work applications, where exacting demands are imposed on wear resistance. |

Certification

1.3243 high speed steel is available with a cast and analysis certificate or a BS EN 10204 3.1 mill certificate, please request when placing any orders.

Quality Assured Supply

1.3243 high speed steel is supplied in accordance with our ISO 9001 : 2008 registration.

Contact our experienced sales team to help you with your 1.3243 HSS materials.

questionsadn enquiry by Email or Telphone. The questions will be reply in 24 hours.

Email: Jack@otaisteel.com

Tel: +86-769- 23190193

Fax: +86-769-88705839