AISI A8 Tool Steel plate-SAE A8 steel round bar

OTAI SPECIAL STEEL is A8 steel stockholders and suppliers from china. more 16 years experience in AISI A8 tool steel round bar, flat bar and plate supply.

AISI A8 is a high quality Cold work tool steel, It belong to the high quality medium carbon high Cr, Mo, V alloy tool steel. Oil Quenched & Tempered Hardenss is 28-34 HRc. AISI A8 steel Annealing delivery hardenss less than 250HB. Cold work tool steel A8 an excellent choose for applications that require higher toughness than that of the high-carbon, high-chromium steels such as D2 tool steel & better wear resistance than that of shock-resisting steels such as S7 steel.

A8 tool steel properties as below:

Related Specifications ASTM A681 DIN EN 10083/3 JIS G4401 GB/T 1299

Form of Supply

AISI A8 tool steel, we can supply the round bar, steel flat bar, plate, hexagonal steel bar and steel square block. AISI A8 steel Round bar can be sawn to your required lengths as one offs or multiple cut pieces. A8 steel Rectangular pieces can be sawn from flat bar or plate to your specific sizes. Ground tool steel bar can be supplied, providing a quality precision finished bar to tight tolerances.

- Round

- sheet

- Square

- Plate

Chemical composition

| C(%) | 0.50~0.60 | Si(%) | 0.75~1.10 | Mn(%) | 0.20~0.50 | P(%) | ≤0.030 |

| S(%) | ≤0.030 | Cr(%) | 4.75~5.50 | Mo (%) | 1.15~1.65 | V(%) | 1.00~1.50 |

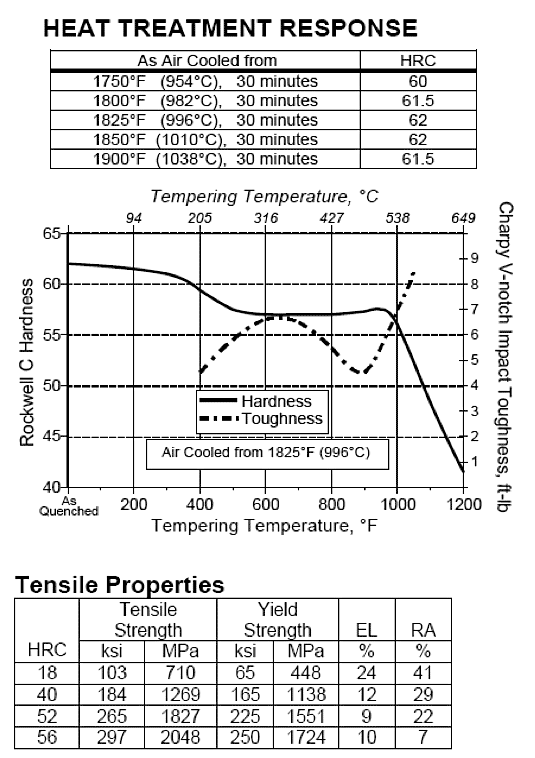

Heat treatment Related

- Forged of A8 Cold Tool steel

Slowly heated the A8 steel material to 650-680°C (1202-1256°F) before raising the temperature to 1050-1100°C (1922-2120°F) and soak A8 material until uniformly heated. Initial hammer blows should be light due to the comparatively high hot strength of this steel.

The A8 steel forged temperature should be maintained above 1000°C(1832℉) until the A8 metal begins to yield. Final forged should not be done below 900°C(1652℉). Slowly cool after forged is essential to avoid the possibility of cracking.

- Annealing of A8 Tool steel

Pre-heated to 788 ℃(1450℉),The Slowly heated A8 steel to 830-845 ℃(1526-1553°F) and allow enough times, let the steel to be thoroughly heated, Then cool slowly in the furnace at a rate of 4°C (40°F) per hour or less.. The A8 tool steel will get MAX 250 HB (Brinell hardness).

- Hardening of Cold work tool steel A8

Put the A8 steel in Air, pressurized gas, or interrupted oil to 65-52℃(150-125°F). Soak thoroughly at the temperature for thirty minutes per 25mm of ruling section, then cool or quench accordingly. Pls Attention: Sizes over 5 inches in cross section may not achieve full hardness by cooling in still air. It is usually necessary to increase the quench cooling rate between 760-482℃(1400 to 900°F )by using an air blast, pressurized gas, or an interrupted oil quench. For the oil quench, quench until black, about 900°F, then cool in still air to 66-52℃(150-125°F).Then withdraw A8 steel tools from the furnace,either air cool or oil quench.

- Tempering of A8 tool steel

Tempering of A8 steels is performed at 148-315°C (300-600°F), Double tempering is recommended for tempering temperatures of 900°F and higher.Soak well at the selected temperature and soak for at least one hour per 25mm of total thickness. Below only for reference.

Mechanical Properties

The mechanical properties of A8 tool steels are outlined in the following table.

| Bulk modulus (typical for steels) | Machinability (based on carbon tool steel) | Shear modulus | Poisson’s ratio | Elastic modulus) | Thermal expansion | |

| GPa | GPa | GPa | 70-800℃ | |||

| 140 | 65% | 78 | 0.27-0.30 | 190-210 | 6.65 x 10-6 in/in/°F | |

Applications

A8 steels are mainly used for slitters, die shapes.

Typical applications include Punches, drift pins, pneumatic tools, chuck jaws, hammers, hot rolls, and hot and cold shear knives, etc.

Regular size and Tolerance

| 1) Hot Rolled round bar | |||

| Diameter (mm) |

Diameter Tolerance (mm) |

Diameter (mm) |

Diameter Tolerance (mm) |

| ≤12.70 | -0.13 ~0.30 | >50.80~63.5 | -0.25~0.76 |

| 12.7~25.40 | -0.13~0.41 | >63.50~76.20 | -0.25~1.02 |

| >25.4~38.10 | -0.15~0.51 | >76.20~101.60 | -0.30~+1.27 |

| >38.1~50.80 | -0.20~0.64 | >101.60~203.20 | -0.38~3.81 |

| 2) Hot Rolled steel plate | |||

| Thickness (mm) |

Thickness Tolerance (mm) |

Thickness (mm) |

Thickness Tolerance (mm) |

| ≤25.4 | -0.41~0.79 | >127~152 | -1.60~2.39 |

| >25.4~76 | -0.79~1.19 | >178~254 | -1.98~3.18 |

| >76~127 | -1.19~1.60 | >254~305 | -2.39~3.96 |

Others A8 have not specified size, pls contact our experienced sales team.

AISI A8 tool steel round bar and flat sections can be cut to your required sizes. A8 ground bar can also be supplied, providing a high quality tool steel precision ground tool steel bar to your required tolerances. AISI A8 steel is also available as Ground Flat Stock / Gauge Plate, in standard and nonstandard sizes.

Contact our experienced sales team to help you with your A8 tool steel questionsadn enquiry by Email or Telphone. The A8 steel questions will be reply in 24 hours.