1.3343 steel is the HSS type steel. HSS refers to high speed steel grade.1.3343 steel is a medium alloyed high speed steel with good cutting performance. The HSS 1.3343 steel chemical composition has good balance toughness, wear resistance and red hardness characteristics. Widely used in cutting tools such as twist drills, taps, milling cutters, saws, and tools. It is also commonly used in cold working presses and dies as well as in high speed and light cutting applications.

1.3343 steel has become the most widely used high speed steel to replace T1 grade high speed steel due to its superior performance and relative economy.

The 1.3343 steels available on the global market are as below:

-Flat bars

-Blocks

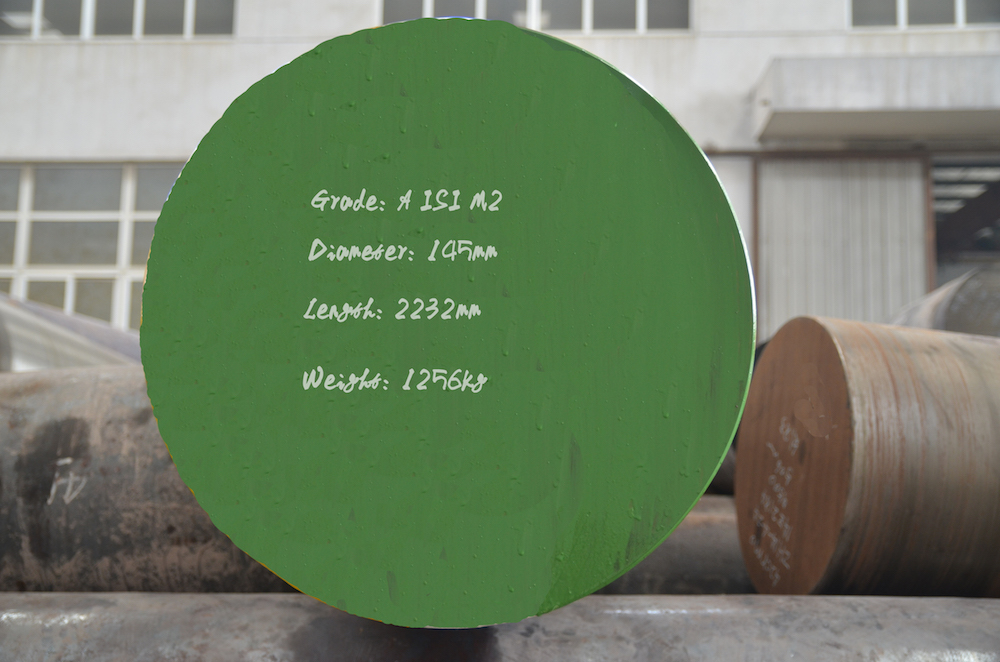

-Round bars

-Square bars

-Sheets

Form of Supply

we can supply the round bar, flat, plate and 1.3343 steel square block. 1.3343 round bar can be sawn to your required lengths as one offs or multiple cut pieces. 1.3343 high speed tool steel Rectangular pieces can be sawn from flat bar or plate to your specific sizes. 1.3343 Ground bar can be supplied, providing a quality precision finished bar to tight tolerances.

- Round

- sheet

- Plate

- Square

1.3343 Tool Steel Material Equivalent and Related Speciations

| USA | German | Japan | China | ISO |

| ASTM A681 | DIN 17350 | JIS G4403 | GB/T 9943 | ISO 4957 |

| M2 | 1.3343 | SKH51 | W6Mo5Cr4V2 | HS 6-5-2 |

Chemical Composition contrast of 1.3343 high speed tool steel with other Equivalent HSS steel Material

| Grade NO. | C(%) | Si(%) | Mn(%) | P(%) | S(%) | Cr(%) | Mo(%) | V(%) | W(%) |

| M2 | 0.78~0.88 | 0.20~0.45 | 0.15~0.40 | ≤0.030 | ≤0.030 | 3.75~4.50 | 4.50~5.50 | 1.75~2.20 | 5.50~6.75 |

| 1.3343 | 0.86~0.94 | ≤0.45 | ≤0.40 | ≤0.030 | ≤0.030 | 3.80~4.50 | 4.70~5.20 | 1.70~2.00 | 6.00~6.70 |

| SKH51 | 0.80~0.88 | ≤0.45 | ≤0.40 | ≤0.030 | ≤0.030 | 3.80~4.50 | 4.70~5.20 | 1.70~2.10 | 5.90~6.70 |

| W6M5Cr4V2 | 0.80~0.90 | 0.20~0.45 | 0.15~0.40 | ≤0.030 | ≤0.030 | 3.80~4.40 | 4.50~5.50 | 1.75~2.20 | 5.50~6.75 |

Heat Treatment of 1.3343 steel:

1.Soft annealing:

820 to 850 °C for about 2 to 5 hours

slow controlled cooling of 10 to 20 °C per hour to about 550 °C;

further cooling in air. Maximum 270 HB

2.Hardening:

1190 – 1230 °C

Quenching in oil/compressed gas/air/hot bath

obtainable hardness: 66 HRC

3.Tempering:

slow heating to tempering temperature (to avoid forming of cracks)

immediately after hardening;

triple tempering is recommended

Applications of 1.3343 Steels

Standard high speed steel grade. The alloy has a balanced composition, high toughness, good cutting force and wide application range. Applications included:

Making of General tools

Making of hot formed tool bits

Making of cold extrusion dies

Making of twist drills

Making of milling tools

Making of metal saws

Making of plastic molds

Making of broaching tools and taps

Making of extrusion rams and dies

Making of circular saw segments

Making of cutting precision tools

Making of wear resistant screws, threaded tools etc.

Processing of 1.3343 steel

1.3343 High Speed tool steel round bar and flat sections can be cut to your required sizes. 1.3343 steel bar can also be supplied, providing a high quality tool steel precision ground tool steel bar to your required tolerances. 1.3343 High Speed steel also is available as Ground Flat Stock / Gauge Plate, in standard and nonstandard sizes.

Contact

Contact our experienced sales team to help you with your 1.3343 Steel questions.by Email or Telphone.

The questions will be reply in 24 hours.

Email: Jack@otaisteel.com

Tel: +86-769- 23190193

Fax: +86-769-88705839