4140 Cold Rolled Steel: Properties, Applications & Processing Tips

4140 Cold Rolled Steel: Properties, Applications & Processing Tips

When it comes to medium-carbon alloy steels, 4140 steel is one of the most widely used grades in demanding engineering and manufacturing applications. Known for its excellent strength, toughness, and wear resistance, it offers enhanced mechanical properties over hot rolled steel thanks to the cold rolling process. This makes it ideal for critical parts that require precision and superior surface finish.

In this guide, we’ll dive into composition, mechanical properties, advantages, applications, and processing considerations for 4140 cold rolled steel—plus share practical insights for engineers, machinists, and buyers.

🌟 What is 4140 Cold Rolled Steel?

4140 steel is a chromium-molybdenum (chromoly) medium-carbon alloy steel with about 0.38–0.43% carbon, 0.8–1.1% chromium, and 0.15–0.25% molybdenum. These alloying elements give it a perfect balance of hardness, strength, and toughness.

The term “cold rolled” refers to a secondary finishing process in which the steel is rolled at room temperature after hot rolling. This process:

-

Improves dimensional accuracy

-

Increases strength through strain hardening

-

Produces a smooth, uniform surface finish

-

Enhances straightness and flatness

📏 4140 Cold Rolled Steel Chemical Composition

| Element | Percentage (%) |

|---|---|

| Carbon (C) | 0.38 – 0.43 |

| Chromium (Cr) | 0.80 – 1.10 |

| Molybdenum (Mo) | 0.15 – 0.25 |

| Manganese (Mn) | 0.75 – 1.00 |

| Silicon (Si) | 0.15 – 0.30 |

| Phosphorus (P) | ≤ 0.035 |

| Sulfur (S) | ≤ 0.040 |

⚙️ Mechanical Properties of 4140 Cold Rolled Steel

| Property | Value (Typical) |

|---|---|

| Tensile Strength | 850 – 1000 MPa |

| Yield Strength | 700 – 800 MPa |

| Elongation | 18 – 25% |

| Rockwell Hardness (B) | 95 – 100 HRB |

| Impact Toughness | Excellent |

| Modulus of Elasticity | ~205 GPa |

Values can vary depending on exact cold rolling and heat treatment conditions.

🔍 Benefits of Using Cold Rolled 4140 Steel

Compared to its hot rolled counterpart, 4140 cold rolled steel offers:

-

Higher Dimensional Accuracy – Ideal for parts requiring tight tolerances without extensive machining.

-

Improved Strength – Cold work increases yield and tensile strength.

-

Better Surface Finish – Smooth, uniform finish reduces post-processing.

-

Enhanced Flatness & Straightness – Important for precision components.

-

Reduced Machining Time – Less stock removal needed before final sizing.

🛠 Applications of 4140 Steel

Its combination of high strength, toughness, and machinability makes it perfect for:

-

Gears and shafts in heavy machinery

-

Automotive components such as axles and crankshafts

-

Tooling parts like dies and molds

-

Hydraulic components including cylinder rods

-

High-strength fasteners

-

Military and defense applications requiring impact resistance

🏭 Processing Considerations

Although cold rolled 4140 steel has excellent machinability, it’s still a tough alloy. Here are some key points to consider:

🔧 Machining

-

Use carbide or coated HSS tools for optimal tool life.

-

Apply cutting fluid to manage heat and extend tool wear.

-

Preheat to 150–200°C before heavy machining to reduce risk of cracking in hardened states.

🔥 Heat Treatment

4140 cold rolled steel can be quenched and tempered to achieve a wide range of hardness levels (up to ~50 HRC). Common heat treatment steps:

-

Annealing – 800–850°C followed by slow cooling to soften and improve machinability.

-

Quenching – Oil quench from 840–870°C.

-

Tempering – 200–600°C depending on required hardness/toughness balance.

➰ Forming & Bending

-

Best performed in the annealed condition.

-

Cold bending is possible but requires adequate tooling and allowances for springback.

📌 Comparison: 4140 Cold Rolled vs Hot Rolled

| Feature | Cold Rolled 4140 | Hot Rolled 4140 |

|---|---|---|

| Dimensional Tolerance | High | Moderate |

| Surface Finish | Smooth & clean | Rough & scaly |

| Strength | Higher | Lower |

| Cost | Higher | Lower |

| Machining Prep | Minimal | Often requires cleaning & facing |

💡 Expert Tips for Buyers

-

When ordering 4140 cold rolled steel, always specify size, tolerance, and desired hardness.

-

For critical components, request UT testing (Ultrasonic Testing) to ensure internal soundness.

-

Partner with a reliable steel distributor who stocks a wide range of sizes to reduce lead time.

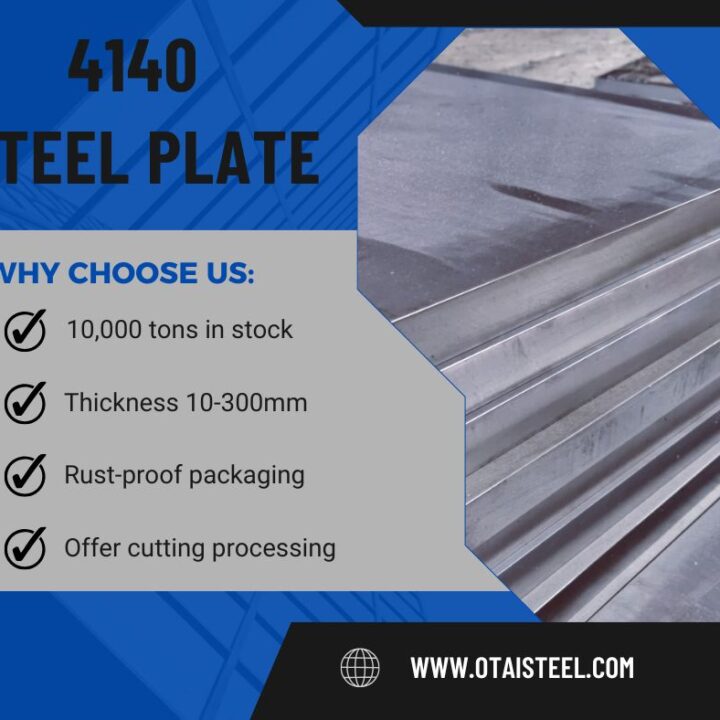

🏆 Company Advantages – Otai Special Steel

-

Massive Stock – Over 10,000 tons of 4140 alloy steel in various sizes and conditions.

-

Custom Processing – Cutting, heat treatment, and precision machining available.

-

Quality Control – UT testing, chemical composition analysis, and third-party inspections (SGS, BV).

-

Global Supply – Serving leading corporations worldwide with stable supply and competitive pricing.

-

Expert Support – Technical guidance for material selection, machining, and heat treatment.

❓ FAQ

Q1: Is 4140 cold rolled steel more expensive than hot rolled?

Yes, but the added benefits in precision, strength, and surface quality often offset the cost.

Q2: Can cold rolled 4140 be welded?

Yes, but preheating (150–300°C) and post-weld stress relief are recommended to avoid cracking.

Q3: What is the maximum hardness after heat treatment?

Proper quenching and tempering can achieve up to ~50–55 HRC.

Q4: Which industries use it the most?

Automotive, aerospace, oil & gas, defense, and general engineering.