4140 Steel Carbon Content – Why It Matters for Strength and Performance

4140 Steel Carbon Content – Why It Matters for Strength and Performance

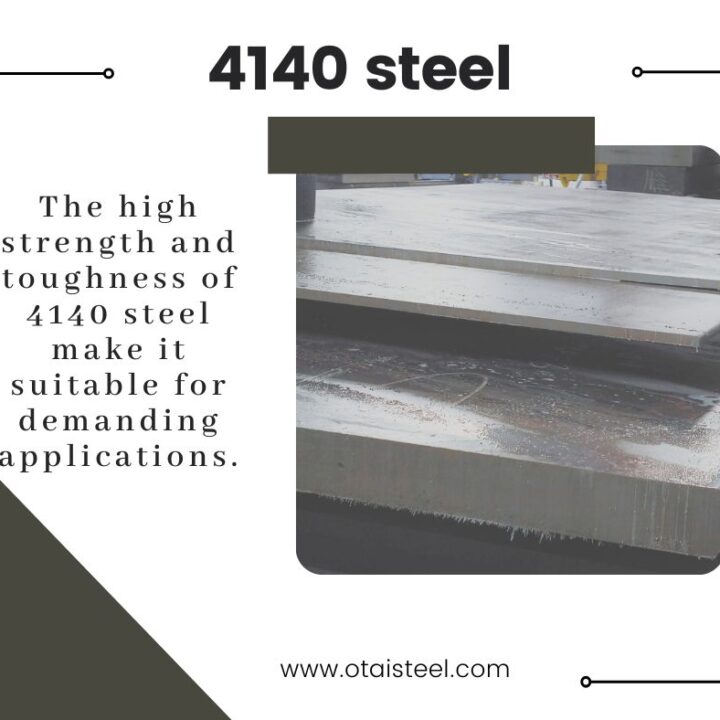

When it comes to alloy steels, 4140 steel carbon content is one of the most discussed aspects. Engineers, machinists, and buyers often want to know: How much carbon does 4140 steel have, and how does it affect its properties? Let’s break it down in detail and see why this specific percentage of carbon makes 4140 steel a favorite in industries like automotive, oil & gas, tooling, and heavy machinery.

✨ What Is the Carbon Content in 4140 Steel?

4140 steel belongs to the chromium-molybdenum alloy steel family. Its carbon content typically ranges between 0.38% and 0.43%, which places it in the medium-carbon steel category.

Here’s a simplified breakdown of its main composition:

| Element | Typical Percentage (%) |

|---|---|

| Carbon (C) | 0.38 – 0.43 |

| Chromium (Cr) | 0.80 – 1.10 |

| Molybdenum (Mo) | 0.15 – 0.25 |

| Manganese (Mn) | 0.75 – 1.00 |

| Silicon (Si) | 0.15 – 0.35 |

| Iron (Fe) | Balance |

This carbon range in 4140 steel is crucial—it gives a perfect balance of hardness, toughness, and machinability. Too little carbon would make the steel too soft, while too much would make it hard but brittle.

🔧 Why Carbon Content Matters

The carbon level in 4140 steel plays a direct role in the following properties:

-

Hardness & Strength

-

With ~0.4% carbon, 4140 can reach Rockwell hardness values in the 28–32 HRC range when normalized, and even higher after quenching and tempering.

-

-

Toughness & Impact Resistance

-

The medium carbon level allows it to resist cracking under stress, unlike high-carbon steels that may become brittle.

-

-

Weldability

-

While weldable, preheating is often required because the carbon content makes it more prone to cracking compared to low-carbon steels.

-

-

Heat Treatment Response

-

The carbon composition of 4140 steel makes it highly responsive to quenching and tempering, giving flexibility in achieving different mechanical properties.

-

⚙️ 4140 Steel Carbon Content vs. Other Steels

To see why 4140 steel carbon percentage is so important, let’s compare it with other common steels:

| Steel Grade | Carbon Content (%) | Characteristics |

|---|---|---|

| A36 (mild steel) | ~0.25 | Excellent weldability, but low strength |

| 1045 (medium carbon) | 0.43 – 0.50 | Higher hardness, lower toughness |

| 4140 alloy steel | 0.38 – 0.43 | Balanced strength, toughness, wear resistance |

| 8620 alloy steel | 0.18 – 0.23 | Low carbon core, good for carburizing |

This comparison shows that 4140’s carbon range is the sweet spot between strength and ductility, making it versatile for demanding applications.

🛠 Applications Driven by 4140 Steel Carbon Level

Because of its controlled carbon percentage, 4140 is widely used in parts that need both toughness and wear resistance:

-

Automotive components: crankshafts, connecting rods, gears

-

Oil & gas industry: drill collars, tool joints

-

Tooling: dies, fixtures, cutting tools

-

Machinery: shafts, spindles, and axles

The 4140 steel carbon makeup ensures these components don’t fail under cyclic stress and impact loads.

🔥 Heat Treatment and Carbon Synergy

The carbon concentration in 4140 steel determines how well it responds to heat treatments:

-

Annealing: improves machinability while reducing hardness

-

Quenching + Tempering: enhances strength up to 95,000–160,000 psi tensile strength

-

Nitriding: creates a hard surface layer (~60 HRC) while keeping the core tough

Without its precise carbon level, 4140 would not achieve this balance of hardness and toughness through heat treatment.

🌍 Global Standards and Designations

Depending on where you are, 4140 may be listed under different standards, but the carbon composition remains consistent:

-

AISI 4140 (USA)

-

DIN 1.7225 (Europe/Germany)

-

42CrMo4 (EN standard)

-

SCM440 (Japan)

No matter the name, the carbon percentage in 4140 steel is what makes these equivalents perform similarly.

🏆 Company Advantages – Why Choose OTAI Steel

At OTAI Special Steel, we supply 4140 alloy steel plates, bars, and tubes with full traceability and strict chemical composition control. Our advantages include:

-

✅ Over 10,000 tons in stock, including thicknesses 6mm–300mm

-

✅ UT-tested & composition-certified for quality assurance

-

✅ Custom services: cutting, heat treatment, and machining

-

✅ Long-term supply to top international companies like Thyssenkrupp & Schlumberger

-

✅ Competitive pricing with fast worldwide delivery

❓ FAQ on 4140 Steel Carbon Content

Q1: What is the exact carbon percentage in 4140 steel?

A: It ranges from 0.38% to 0.43%, making it a medium-carbon alloy steel.

Q2: How does carbon content affect 4140’s weldability?

A: The higher carbon level requires preheating and post-weld stress relief to avoid cracking.

Q3: Can 4140 be surface hardened due to its carbon level?

A: Yes, processes like carburizing or nitriding are very effective.

Q4: Why not use higher carbon steel for strength instead?

A: Too much carbon reduces toughness and ductility, making the material brittle.

Q5: Is the carbon percentage the same across global equivalents?

A: Yes, equivalents like DIN 1.7225, 42CrMo4, and SCM440 maintain the same carbon range.