4140 Steel in SolidWorks – How to Use It for Accurate Design & Simulation

4140 Steel in SolidWorks – How to Use It for Accurate Design & Simulation

If you work with mechanical design or FEA, you’ve probably wondered how to set up 4140 steel in SolidWorks correctly. Whether you’re designing shafts, gears, or machine frames, using the right material data is essential for realistic results. In this article, we’ll show you how to add 4140 steel material properties in SolidWorks, set its density, yield strength, and even run simulations with confidence.

🏗️ Why 4140 Steel Matters in SolidWorks

4140 is a chromium-molybdenum alloy steel known for its balance of strength, toughness, and machinability. In SolidWorks, choosing the wrong material or leaving it as “Plain Carbon Steel” can lead to inaccurate weight, stress, and deflection predictions.

Using 4140 steel in SolidWorks ensures:

- Correct mass calculation for weight-sensitive parts

- Accurate center of gravity for assemblies

- Proper stress results in FEA (finite element analysis)

- Reliable factor of safety predictions

- Precise bill of materials for purchasing

⚙️ Adding 4140 Steel to the Material Library

By default, SolidWorks doesn’t include every steel grade in its library. To add 4140 steel material properties in SolidWorks:

- Open the Material Library – Right-click on “Material” in the Feature Manager > Edit Material.

- Create a Custom Material – Select a custom material folder and click New Material.

- Enter Density – Input 0.284 lb/in³ (7.85 g/cm³) under the Physical Properties tab.

- Add Mechanical Properties –

- Yield Strength: ~95,000 psi (655 MPa)

- Tensile Strength: ~150,000 psi (1,034 MPa) (quenched & tempered)

- Elastic Modulus: 29,000 ksi (200 GPa)

- Poisson’s Ratio: 0.29

- Save the Material – Give it a clear name like “AISI 4140 QT”.

This step ensures every part or assembly that uses this material will have consistent data.

⚖️ SolidWorks 4140 Steel Density

SolidWorks uses density to compute weight and mass properties. If you model a 2″ × 2″ × 36″ bar with 4140 steel density, you’ll get:

- Volume = 144 in³

- Weight = 144 × 0.284 = 40.9 lbs

This matches handbook values and ensures accurate BOMs and shipping weight estimates.

📈 SolidWorks 4140 Steel Yield Strength in Simulation

When running Simulation studies, SolidWorks uses yield strength to determine factor of safety. Entering the correct 4140 steel yield strength (~95 ksi) helps predict:

- Permanent deformation under loads

- Safety margins in shafts and frames

- Stress concentrations around fillets or holes

💡 Tip: If you use different heat treatments (annealed, normalized, quenched & tempered), update the yield and tensile strength values accordingly.

🖥️ Running FEA with 4140 Steel

Once the material is applied, you can run static, frequency, or fatigue studies.

Example: A crankshaft modeled in 4140 steel:

- Apply torque loads

- Fix bearing surfaces

- Run a static study

- Check maximum von Mises stress against 95 ksi yield strength

This allows you to determine if the shaft design is safe before manufacturing.

📊 Table: Typical 4140 Steel Properties for SolidWorks Input

| Property | Value |

|---|---|

| Density | 0.284 lb/in³ (7,850 kg/m³) |

| Elastic Modulus | 29,000 ksi (200 GPa) |

| Poisson’s Ratio | 0.29 |

| Yield Strength | 95,000 psi (655 MPa) |

| Tensile Strength | 150,000 psi (1,034 MPa) |

| Shear Modulus | 11,500 ksi (79 GPa) |

🔧 Best Practices for Using 4140 in SolidWorks

- Keep a custom material database so the whole design team uses the same data.

- Document which heat-treatment condition you’re using.

- Use mass properties tool to double-check weight before ordering material.

- Validate simulation results with hand calculations or reference data.

- If needed, run a sensitivity study to see how design changes affect stress and weight.

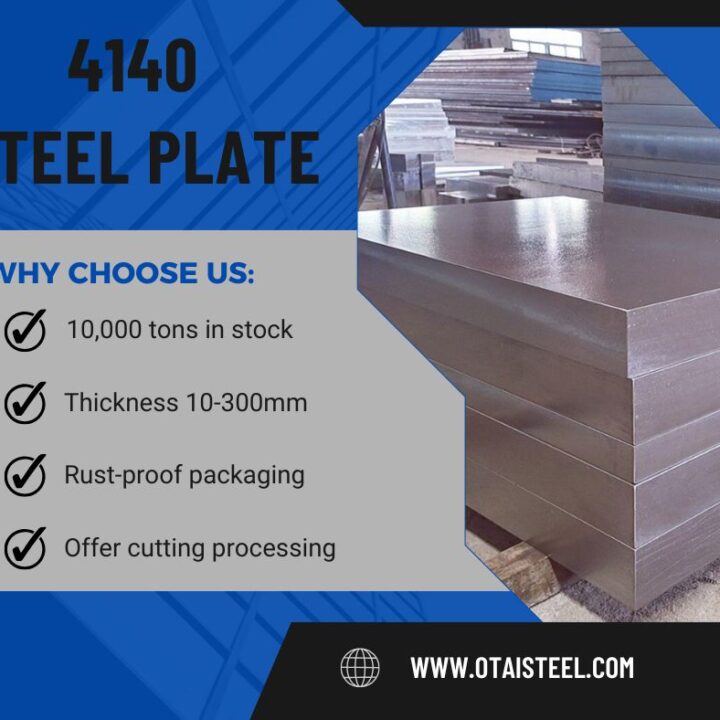

🌟 Company Advantages

At Otai Special Steel, we provide customers with accurate 4140 steel mechanical property data that you can plug directly into SolidWorks. We offer:

- 10,000+ tons of 4140 in stock, all with certified MTCs

- Data sheets with density, yield strength, and modulus

- Custom heat treatment services so you can match simulation to real-world conditions

- Pre-cut blanks to save machining time and reduce material waste

This makes your CAD and simulation process more reliable and efficient.

❓ FAQ

Q: Does SolidWorks have 4140 steel by default?

A: No, you must create a custom material or import from a material database.

Q: Which heat treatment should I use in simulation?

A: Choose the condition that matches your final part — annealed for machinability, quenched & tempered for strength.

Q: Will density change after heat treatment?

A: Not significantly. You can use the same value across conditions.

Q: Can I share my custom 4140 material file with my team?

A: Yes, copy the .sldmat file to a shared network folder for consistent results.

Q: How do I verify that my weight matches reality?

A: Compare SolidWorks mass properties with supplier-provided weight charts before production.