When it comes to 4140 steel, normalization is one of the most effective heat treatments for improving its toughness, machinability, and structural consistency. But what exactly does “4140 steel normalized” mean—and how does it affect performance in real-world applications like shafts, gears, or hydraulic parts?

Let’s dive in and break it down! 🧐

🔍 What Does “Normalized” Mean for 4140 Steel?

Normalization is a heat treatment process in which 4140 steel is heated to a temperature above its critical range—typically around 870–925°C (1600–1700°F)—and then air-cooled. This refines the grain structure, removes internal stresses, and ensures uniformity across the material.

Here’s how the process works step by step:

| Step | Description |

|---|---|

| Heating | Heated to around 870–925°C (1600–1700°F) |

| Soaking | Held at temperature long enough for transformation |

| Cooling | Air-cooled at room temperature (not quenched) |

🧠 Why Normalize 4140 Steel?

Normalizing 4140 steel provides multiple benefits, especially when the steel will undergo further machining, welding, or hardening. Here’s what normalization achieves:

| Benefit | Explanation |

|---|---|

| Improved Toughness | Finer, more consistent grain structure helps resist cracking and impact. |

| Better Machinability | Softened structure makes it easier to cut and shape. |

| Uniform Microstructure | Critical for performance and strength consistency. |

| Relief of Internal Stress | Especially important after forging or rolling. |

🔬 Mechanical Properties of Normalized 4140 Steel

Normalization changes some mechanical properties of 4140 steel. The exact values depend on the cooling rate and section size, but here’s a general overview:

| Property | Typical Value (Normalized Condition) |

|---|---|

| Tensile Strength | 850–1000 MPa |

| Yield Strength | 650–800 MPa |

| Elongation | 20–25% |

| Hardness (Brinell) | 200–250 HB |

| Impact Toughness (Charpy V-notch) | ≥ 35 J at room temp |

Compared to as-rolled or annealed 4140, the normalized version strikes a balance between strength and machinability.

🧪 Microstructure After Normalizing

After normalization, 4140 steel typically has a uniform microstructure composed of fine pearlite and ferrite. This is ideal for:

-

Reducing micro-segregation from casting or forging

-

Creating a more stable base for future quenching and tempering

-

Avoiding brittle zones that can lead to premature failure

Here’s a basic schematic:

| State | Microstructure |

|---|---|

| As-rolled | Coarse pearlite + ferrite (non-uniform) |

| Normalized | Fine pearlite + ferrite (uniform, stress-free) |

| Quenched & tempered | Martensite + tempered phases (very strong, less machinable) |

🛠️ When to Use Normalized 4140 Steel

Normalized 4140 steel is a great choice for applications that require decent strength and toughness, but also need good machinability and dimensional stability.

✅ Common Applications:

-

Shafts & axles

-

Die blocks

-

Machine parts

-

Gears

-

Automotive components

Normalization is often used as an intermediate step before final heat treatments like quenching & tempering.

🆚 Normalized vs Annealed vs Quenched & Tempered

Let’s compare the normalized condition of 4140 alloy with its other common heat-treated forms:

| Condition | Hardness (HB) | Strength | Machinability | Toughness |

|---|---|---|---|---|

| Annealed | 180–200 | Low | Excellent | High |

| Normalized | 200–250 | Medium | Good | High |

| Q&T | 280–320 | High | Moderate | Medium–High |

So, if you want better strength than annealed 4140 but don’t need extreme hardness, normalization is the sweet spot. 🍬

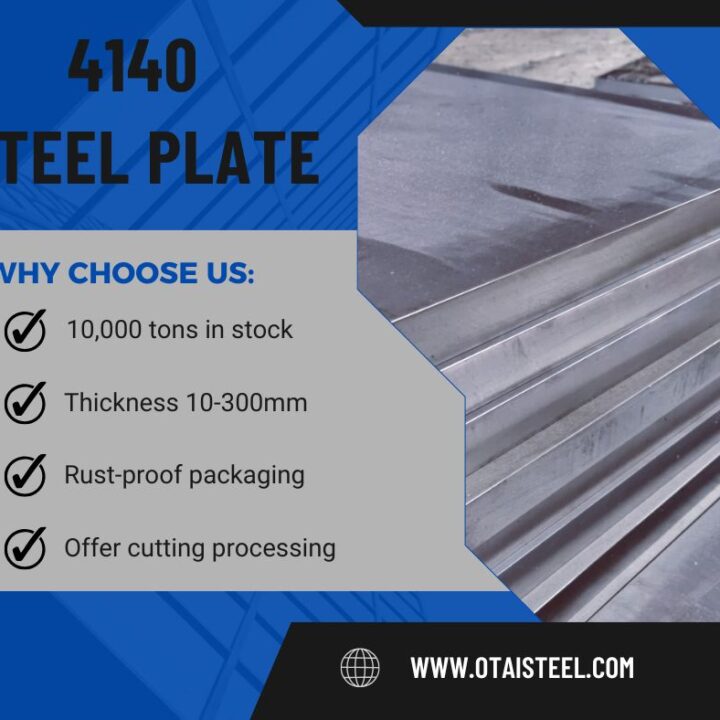

🏭 Otai Special Steel — Why Choose Us?

At Otai Special Steel, we offer 4140 alloy steel plates and bars in normalized, annealed, or quenched & tempered conditions. Here’s why customers around the world trust us:

✨ 10,000+ tons stock ready year-round

🔧 Custom cutting, heat treatment, and packaging services

📐 Thicknesses from 6mm to 300mm

🧪 Certified by UT, SGS, and chemical composition tests

🌍 Clients include top global firms like Thyssenkrupp, Schlumberger, Borealis

Looking for 4140 steel normalized with stable supply and expert processing?

📧 Contact us: jack@otaisteel.com

📱 WhatsApp: +8676923190193

❓FAQ

Q1: Is normalized 4140 steel harder than annealed?

Yes. Normalized 4140 typically has a hardness of 200–250 HB, while annealed steel is around 180–200 HB.

Q2: Can I machine normalized 4140 steel easily?

Yes. It’s tougher than annealed steel but still offers good machinability.

Q3: Does normalized steel need further treatment?

It depends. For higher strength, you may follow up with quenching & tempering.

Q4: What’s the best use case for normalized 4140?

Applications needing moderate strength and good machinability, like shafts, pins, or gears.

Q5: Can Otai supply normalized 4140 steel in bulk?

Absolutely! We offer various sizes and custom services for normalized 4140 steel.