4140 Steel vs A36 Steel: Key Differences You Must Know

4140 Steel vs A36 Steel: Key Differences You Must Know

When it comes to selecting the right material for engineering or industrial projects, two commonly discussed steels are 4140 steel and A36 steel. At first glance, both may look similar, but their chemical composition, mechanical properties, and applications are quite different. In this article, we will break down the differences between these steels, discuss where each is best used, and help you decide which one suits your project.

✨ Overview of 4140 Steel

4140 steel is a chromium-molybdenum alloy steel known for its excellent strength, toughness, and wear resistance. It belongs to the medium-carbon steel family and is widely used in critical components requiring high fatigue strength and durability.

-

Type: Alloy steel (Cr-Mo steel)

-

Carbon content: ~0.38–0.43%

-

Heat treatable: Yes (quenched and tempered)

-

Applications: Shafts, gears, crankshafts, axles, dies, and heavy-duty machine parts

4140 steel is often selected when the project demands both strength and toughness, particularly under stress and fatigue.

⚡ Overview of A36 Steel

A36 steel is one of the most widely used structural steels in construction and fabrication. It is a low-carbon steel with good weldability and ductility, but its strength is significantly lower than 4140 steel.

-

Type: Mild carbon steel

-

Carbon content: ~0.25% max

-

Heat treatable: Limited hardening (generally not used for high-strength applications)

-

Applications: Building structures, bridges, plates, beams, and general fabrication

A36 steel is commonly chosen for structural applications where high strength is not as critical, but cost-effectiveness and weldability are more important.

🔍 4140 Steel vs A36 Steel – Chemical Composition

| Element | 4140 Steel (%) | A36 Steel (%) |

|---|---|---|

| Carbon (C) | 0.38–0.43 | ≤ 0.25 |

| Chromium (Cr) | 0.8–1.1 | — |

| Molybdenum (Mo) | 0.15–0.25 | — |

| Manganese (Mn) | 0.75–1.0 | 0.8–1.2 |

| Silicon (Si) | 0.15–0.35 | 0.4 max |

| Phosphorus (P) | ≤ 0.035 | ≤ 0.04 |

| Sulfur (S) | ≤ 0.04 | ≤ 0.05 |

👉 As seen above, 4140 steel includes chromium and molybdenum, which significantly enhance strength, toughness, and wear resistance—properties A36 steel lacks.

📊 Mechanical Properties Comparison

| Property | 4140 Steel (quenched & tempered) | A36 Steel |

|---|---|---|

| Yield Strength (MPa) | 655–965 | 250 |

| Tensile Strength (MPa) | 850–1000 | 400–550 |

| Hardness (HRC) | 28–32 | ~15 |

| Elongation (%) | 20–25 | 20–23 |

| Modulus of Elasticity | ~205 GPa | ~200 GPa |

Key takeaway: 4140 steel offers almost double the strength and hardness of A36 steel, making it suitable for demanding mechanical parts, while A36 remains a cost-effective choice for structural projects.

🛠️ Applications of 4140 vs A36

-

4140 Steel: Gears, axles, crankshafts, dies, molds, hydraulic components, pressure vessels, drilling equipment

-

A36 Steel: Construction beams, bridges, shipbuilding, general fabrication, base plates, tanks

💡 Which One Should You Choose?

-

If you need high strength, toughness, and wear resistance, especially for mechanical parts → Go with 4140 steel.

-

If you need affordable, weldable, and ductile steel for structural purposes → A36 steel is the better choice.

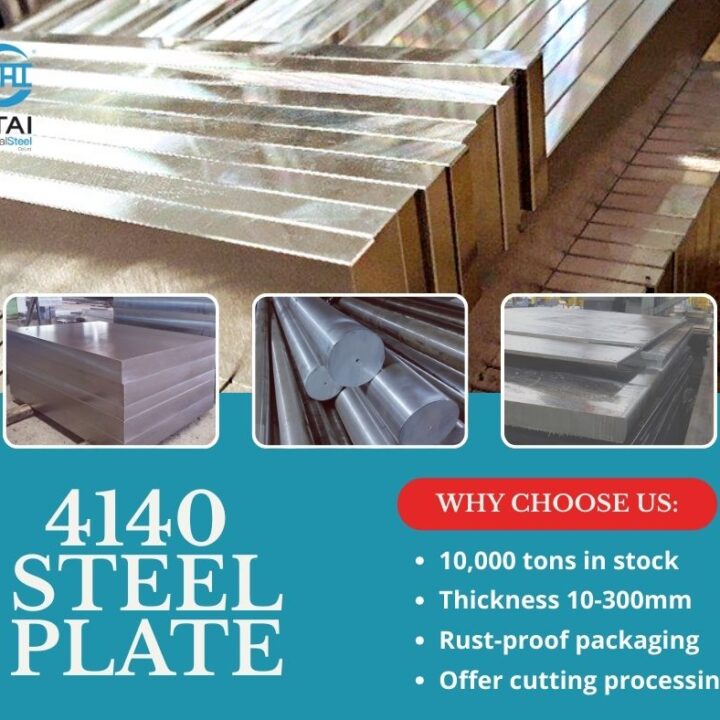

🌟 Company Advantages (Otai Special Steel)

At Otai Special Steel, we maintain a large stock of both 4140 alloy steel plates and other alloy/structural steels. With over 10,000 tons in inventory, we support various dimensions (6mm–300mm thickness) and offer services like:

-

Customized cutting

-

Heat treatment

-

UT and chemical testing

-

SGS third-party inspection

Our clients include top international companies in oil, gas, automotive, and heavy machinery sectors. We guarantee stable supply, competitive pricing, and strict quality control for every order.

❓ FAQ

Q1: Is 4140 stronger than A36?

Yes. 4140 has nearly double the yield strength and much higher hardness compared to A36.

Q2: Can A36 steel be heat treated like 4140?

Not effectively. A36 is mild steel and does not significantly harden with heat treatment.

Q3: Is 4140 steel more expensive than A36?

Yes, due to alloying elements and superior mechanical properties.

Q4: Can both steels be welded?

Yes, but 4140 requires preheating and controlled cooling to avoid cracking, while A36 is easily weldable.

Q5: Which steel is better for heavy-duty gears?

4140 steel is far superior to A36 for gears and mechanical parts.