Is 4140 Steel Strong? Here’s the Straight Answer (With Real-World Insights)

Is 4140 Steel Strong? Here’s the Straight Answer (With Real-World Insights)

We get this question a lot—from engineers, maintenance teams, even procurement managers:

“Is 4140 steel strong enough for my part?”

And it’s a fair question. With so many steels out there (1045, 4340, H13, S7…), it’s easy to get lost comparing specs.

So let’s clear the air:

Yes, AISI 4140 is a strong steel—especially when heat treated.

But how strong it is for your actual application depends on the condition, heat treatment, size, and design environment.

Let’s break it down clearly—so you don’t overpay, under-design, or end up with cracking or premature failure.

🔍 What Makes 4140 “Strong”?

4140 steel is a medium-carbon, low-alloy steel with chromium and molybdenum as strengthening agents. This composition makes it:

-

Heat treatable to high strength and hardness

-

Tough under impact and shock loads

-

Resistant to wear and fatigue

-

Machinable, weldable, and versatile

This unique blend of strength and workability makes it a favorite in industries like:

-

Oil & Gas

-

Automotive

-

Construction equipment

-

Aerospace support components

-

Heavy-duty tooling and machinery

📊 4140 Steel Mechanical Properties – The Real Numbers (Q&T)

Here are the typical values when 4140 is quenched and tempered:

| Property | Typical Value |

|---|---|

| Tensile Strength | 850–1000 MPa (123–145 ksi) |

| Yield Strength | ~655 MPa (95 ksi) |

| Hardness | 28–32 HRC (Q&T) |

| Elongation | ~25% |

| Impact Toughness | 50–60 J (Charpy V at -20°C) |

| Fatigue Strength | Moderate to High |

| Modulus of Elasticity | ~205 GPa |

| Surface Hardness (nitrided) | Up to 55 HRC |

📌 Reminder: These numbers assume proper heat treatment. Annealed or as-rolled 4140 is much weaker—around 600 MPa tensile at best.

🛠 4140 in Action: Where It Really Performs

We’ve supplied 4140 steel to thousands of global clients. Some of the most common parts we see include:

| Component | Why Use 4140 |

|---|---|

| Drive shafts | Handles torque, shock, and wear |

| Threaded rods and studs | Withstands tension without stretching or snapping |

| Hydraulic cylinder rods | Smooth surface + fatigue strength |

| Mold plates & bases | Machinable, wear-resistant, and strong |

| Gear blanks | Can be carburized or nitrided for wear |

| Construction pins | High shear load capacity, impact resistance |

📌 Real case: A client in Canada was using 1045 pins on a mobile crane. They bent under load. We replaced them with Q&T 4140, and the issue disappeared—plus their rework rate dropped 70%.

❗ Misunderstanding #1: “All 4140 is Strong”

Not exactly. Here’s where many get burned:

| Condition | Tensile Strength | Typical Use |

|---|---|---|

| Annealed | 600–650 MPa | Easy machining, NOT for final strength |

| Normalized | 700–800 MPa | Better, but still may need heat treating |

| Quenched & Tempered | 850–1000+ MPa | High strength, ready for load-bearing parts |

| Nitrided (Q&T base) | Surface HRC 50–55 | Surface wear parts like guides, molds |

So—if you want strong, ask for Q&T 4140. We’ve seen buyers accidentally order annealed stock and wonder why the shaft fails under load.

💡 Otai Tip: Always specify condition when ordering. Don’t just say “4140 steel plate”—say “4140 Q&T, 28–32 HRC”.

🔩 Compared with Other Steels – Is 4140 Still Strong?

Absolutely. Here’s a quick benchmark:

| Material | Tensile (MPa) | Strength vs 4140 | Comment |

|---|---|---|---|

| 1045 (medium carbon) | 600–700 | Weaker | No heat treat response |

| 4140 (Q&T) | 850–1000 | — | Balanced strength & toughness |

| 4340 | 930–1100 | Slightly stronger | Better impact toughness, higher cost |

| Mild Steel 1018 | ~440 | Much weaker | Not suitable for high-stress parts |

For 90% of our customers, 4140 is the perfect middle ground: stronger than carbon steel, easier to machine than tool steels, and more available than aerospace-grade alloys.

🔧 Can You Machine or Weld 4140 Steel?

Yes—but there are some best practices:

-

Machining: 4140 in Q&T condition is still machinable with proper carbide tooling.

-

Welding: Can be done, but requires preheating (~200–300°C) and post-weld tempering to avoid cracking.

-

Surface finish: For cylinder rods and wear parts, nitriding after Q&T gives excellent surface hardness without affecting core strength.

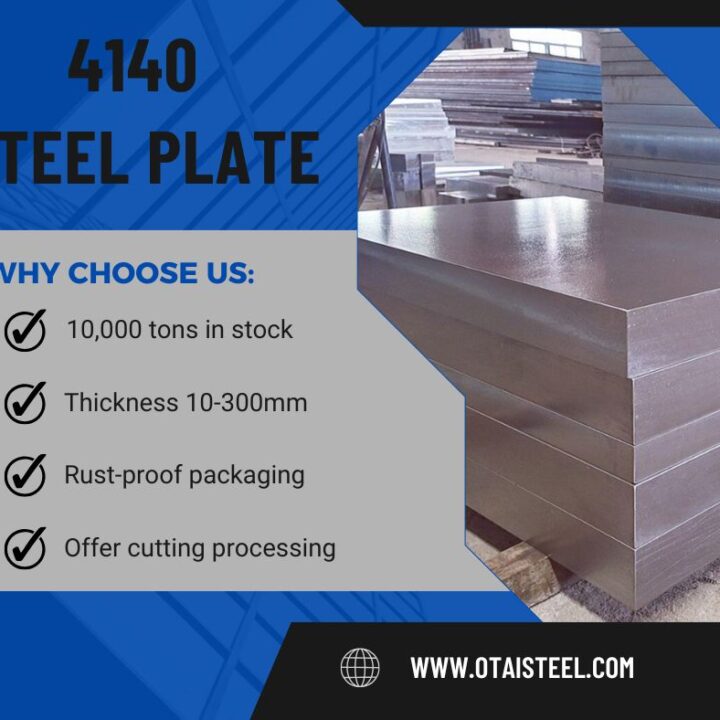

📦 Why Otai Is a Top Choice for 4140 Steel

Clients choose us not just for price—but because we understand what the numbers mean in real life.

-

✅ 10,000+ tons in stock – including 4140 round bars, plates, blocks

-

✅ Heat treatment available: Annealed, Q&T, or Nitrided

-

✅ Precision cutting to your sizes

-

✅ Hardness & UT testing with every order

-

✅ Rust-proof packaging (bundled or boxed)

-

✅ SGS/BV/Intertek inspection on request

-

✅ Serving 30+ countries – from Thailand to Turkey to the US

📧 jack@otaisteel.com

📱 WhatsApp: +8676923190193

Send us your drawing or spec—we’ll check if 4140 is strong enough for your job, or if another grade fits better.

❓FAQs – Is 4140 Steel Strong Enough?

1. Is 4140 stronger than regular carbon steel?

Yes—4140 is significantly stronger than carbon steels like 1045 or 1018, especially after heat treatment.

2. Can 4140 replace 4340 or tool steels?

Sometimes. For general wear or load-bearing, yes. But for extreme impact (e.g., dies, forging), 4340 or tool steel may be better.

3. How hard can 4140 get?

Up to 32 HRC in core (Q&T) and 55 HRC on surface (nitrided), without brittleness.

4. Is 4140 too hard to machine?

No. Even Q&T 4140 (28–32 HRC) machines well with carbide tools. Many mold makers and gear shops prefer it.

5. Can Otai supply 4140 already heat treated or pre-cut?

Absolutely. We offer Q&T, pre-ground, cut-to-size or rough machined steel—just tell us what you need.