Tensile Strength of 4140 Steel: Why It Matters for Your Applications

Tensile Strength of 4140 Steel: Why It Matters for Your Applications

When it comes to strength, 4140 steel doesn’t mess around. 💪 Whether you’re designing high-load gears, crankshafts, or aircraft landing gear, understanding the tensile strength of 4140 steel is key to picking the right material for the job.

But what exactly makes this alloy so dependable? And how does heat treatment or condition affect its performance? Let’s dive deep into the numbers, the real-world impact, and what you need to know before specifying 4140 for your next project.

🔧 What Is Tensile Strength, and Why Should You Care?

Tensile strength measures how much pulling force a material can withstand before breaking. It’s one of the most crucial mechanical properties when selecting steel for components that face high stress, pressure, or dynamic loading.

For AISI 4140 steel, which is a chromium-molybdenum low alloy steel, this property is a big part of its reputation for strength and toughness.

📊 Tensile Strength of 4140 Steel in Different Conditions

Here’s a breakdown of the mechanical properties of 4140 steel, especially tensile strength, under various heat-treated or supply conditions:

| Condition | Tensile Strength (MPa) | Yield Strength (MPa) | Hardness (HRC) | Notes |

|---|---|---|---|---|

| As-rolled / Annealed | 655 – 850 | 415 – 565 | 12 – 22 | Soft and machinable |

| Normalized 4140 steel tensile strength | 850 – 1000 | 655 – 800 | 20 – 25 | Improved strength after normalization |

| Quenched & Tempered (Q&T) @ 200°C | 1250 – 1400 | 1000 – 1150 | 40 – 45 | For maximum strength |

| Tensile strength of hardened 4140 steel | Up to 1550 | Up to 1250 | 48 – 52 | Strong but reduced ductility |

| Stress Relieved | 850 – 1000 | 650 – 800 | 20 – 30 | Balances stress and strength |

*Data is approximate and may vary slightly by mill specifications and testing methods.

🔥 Heat Treatment Makes a Big Difference

The tensile strength of 4140 steel after heat treatment can almost double compared to its annealed condition. Why?

Because 4140 responds extremely well to quenching and tempering. This treatment transforms its microstructure, significantly boosting both yield and tensile strength while maintaining a good balance of toughness.

This makes it ideal for high-stress applications like:

-

Truck axles 🚛

-

Drill collars 🛠

-

Forged crankshafts 🚗

-

Hydraulic tool bodies 🛠

In fact, many engineers refer to the 4140 steel tensile strength chart before making any critical load-bearing part decisions.

🧪 4140 vs Other Common Steels

How does 4140 stack up? Let’s compare with other commonly used steels in a tensile strength context:

| Material | Ultimate Tensile Strength (MPa) | Notes |

|---|---|---|

| 4140 (Q&T) | 1250 – 1400 | High strength, good ductility |

| 1045 (Normalized) | 625 – 750 | Lower strength, easier to machine |

| 4340 (Q&T) | 1350 – 1550 | Higher strength, less available |

| Mild Steel (A36) | ~400 | Low strength, high weldability |

This tensile strength comparison: 4140 vs 1045 clearly shows why 4140 is preferred for critical parts—it offers almost double the strength.

🏭 Application Case: Why a Gear Manufacturer Switched to 4140

A European manufacturer producing large-diameter industrial gears initially used 1045 steel but experienced deformation under high torque.

After switching to 4140 steel and performing stress relieving followed by quenching and tempering, they achieved:

-

80% reduction in gear wear over 12 months

-

Zero gear breakage incidents

-

Improved machining efficiency due to consistent hardness

This real-world use highlights why understanding the tensile properties of 4140 alloy steel is not just academic—it’s practical.

📘 Summary: Is 4140 Steel Strong Enough?

Absolutely. With a tensile strength of up to 1550 MPa, it stands strong against torsion, tension, and impact. And with flexibility in heat treatment, you can tailor it for toughness, ductility, or even shock resistance.

If you’re dealing with structural demands, tensile yield strength of 4140 becomes critical too—it offers around 85–90% of its tensile strength, which is a reliable safety margin.

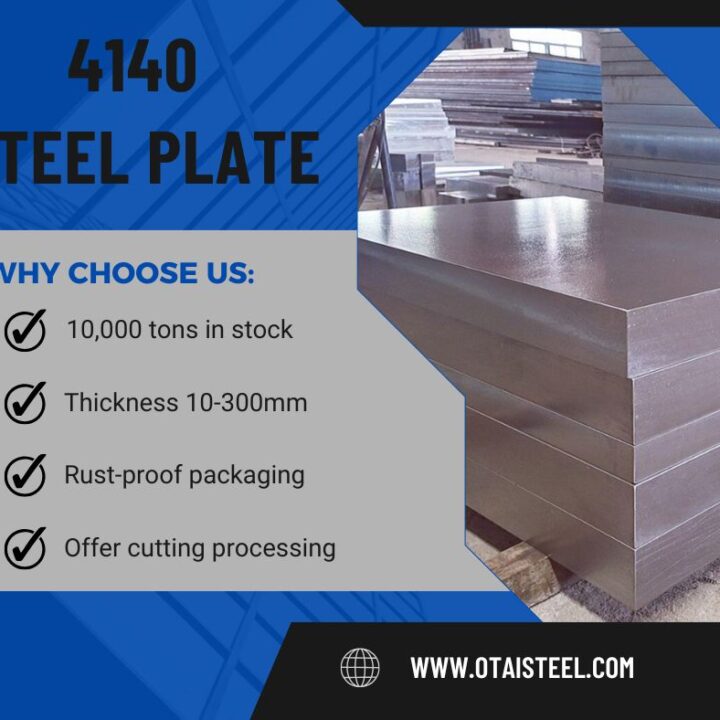

🏭 Company Advantages – Why Choose Otai Special Steel?

At Otai Special Steel, we specialize in supplying top-quality 4140 alloy steel plates and bars, ready for stress relief or further heat treatment. Here’s what sets us apart:

-

📦 Massive inventory: Over 10,000 tons in stock

-

🔍 Quality assurance: UT, chemical testing, third-party inspection

-

✂️ Value-added services: Cutting, pre-machining, custom packaging

-

🌐 Global supply chain: Trusted by clients in over 60 countries

-

🛎️ Responsive service: Fast quotes, technical support, export expertise

Whether you’re working with pre-hardened 4140 or normalized stock, we can deliver it to your exact specs.

📧 Contact us: jack@otaisteel.com

📱 WhatsApp: +8676923190193

❓ FAQ: Tensile Strength of 4140 Steel

Q1: Can I increase 4140’s tensile strength further?

Yes, through proper heat treatment like quenching & tempering or induction hardening.

Q2: Is normalized 4140 good enough for structural parts?

Yes, it offers up to 1000 MPa tensile strength—ideal for medium-load applications.

Q3: How does hardness relate to tensile strength in 4140?

Generally, higher hardness correlates with higher tensile strength, especially in Q&T condition.

Q4: Can I get mill certificates for tensile strength values?

Of course! At Otai, all shipments can be provided with MTC including tensile and hardness data.

Q5: What if I need different strength levels for different parts?

We offer custom heat-treated 4140 products to match your specific mechanical property needs.