Cast 4140 Steel Properties: A Comprehensive Overview

Cast 4140 Steel Properties: A Comprehensive Overview

Cast 4140 steel is a variant of 4140 alloy steel, created using casting methods instead of traditional forging. This steel combines the excellent mechanical properties of 4140 steel, like strength, toughness, and wear resistance, with the flexibility of casting, allowing manufacturers to produce complex and large components. In this article, we’ll explore the properties of cast 4140 steel, including its mechanical characteristics, benefits, and common applications.

🌟 What Is Cast 4140 Steel?

Cast 4140 steel is an alloy containing carbon (C), chromium (Cr), molybdenum (Mo), and manganese (Mn). These alloying elements give it exceptional strength, toughness, and wear resistance. In the casting process, manufacturers pour molten metal into molds, allowing it to cool and solidify into specific shapes. This process makes it possible to produce complex, large, or irregularly shaped parts efficiently.

While the mechanical properties of cast 4140 steel are similar to those of forged 4140 steel, the casting process may slightly affect the internal structure and overall mechanical properties of the material.

🔧 Chemical Composition of Cast 4140 Steel

The chemical composition of cast 4140 steel plays a vital role in determining its mechanical properties. Here is the typical chemical composition:

| Element | Min % | Max % |

|---|---|---|

| Carbon (C) | 0.38 | 0.43 |

| Chromium (Cr) | 0.80 | 1.10 |

| Molybdenum (Mo) | 0.15 | 0.25 |

| Manganese (Mn) | 0.60 | 0.90 |

| Silicon (Si) | 0.20 | 0.35 |

| Sulfur (S) | 0.04 | 0.05 |

| Phosphorus (P) | 0.04 | 0.05 |

These elements provide cast 4140 steel with the strength, wear resistance, and toughness needed for high-performance applications.

🏗️ Mechanical Properties of Cast 4140 Steel

Cast 4140 steel offers impressive mechanical properties, even though the casting process can influence its internal structure. Below are the typical mechanical properties:

| Property | Value |

|---|---|

| Tensile Strength | 850–1000 MPa |

| Yield Strength | 600–900 MPa |

| Elongation | 20%–30% (depends on heat treatment) |

| Hardness | 28–35 HRC |

| Impact Toughness | High resistance to impact and fatigue |

| Fatigue Strength | Excellent fatigue resistance |

1. Tensile Strength

Cast 4140 steel typically has a tensile strength between 850 MPa and 1000 MPa. This allows the steel to withstand significant tensile loads without breaking, making it suitable for heavy-duty applications.

2. Yield Strength

With a yield strength ranging from 600 MPa to 900 MPa, cast 4140 steel resists permanent deformation, maintaining its shape under heavy loads.

3. Elongation

The elongation of cast 4140 steel ranges from 20% to 30%, providing the material with flexibility before it fractures, which helps it resist cracking under stress.

4. Hardness

The hardness of cast 4140 steel falls between 28 and 35 HRC, offering wear resistance while maintaining toughness.

5. Toughness and Fatigue Resistance

One of the standout features of cast 4140 steel is its toughness and fatigue resistance, making it ideal for high-stress environments where cyclic loads are common.

🌍 Advantages of Cast 4140 Steel

The casting process offers distinct advantages, particularly when producing large or complex components. These include:

| Advantage | Description |

|---|---|

| Complex Shapes | Casting allows for the production of intricate, large parts that would be difficult or expensive to forge. |

| Cost-Effective | For large parts, casting is often more economical than forging or machining, particularly in mass production. |

| Consistency | Casting ensures consistent material properties, especially with controlled cooling rates. |

| Design Flexibility | Casting offers more flexibility for creating custom parts with unique shapes. |

🏗️ Applications of Cast 4140 Steel

Due to its excellent mechanical properties, cast 4140 steel finds application in a variety of industries, including:

| Industry | Applications | Why Cast 4140 Steel? |

|---|---|---|

| Automotive | Engine blocks, crankshafts, gears | The casting process is ideal for large, complex components that require strength. |

| Aerospace | Structural components, landing gear parts | High toughness and wear resistance for critical aerospace components. |

| Heavy Machinery | Hydraulic components, machine frames | Strength and fatigue resistance under heavy loads. |

| Oil and Gas | Drill rods, downhole tools, valves | Ability to withstand high pressures and abrasive conditions. |

1. Automotive Industry

In the automotive industry, cast 4140 steel is used for engine blocks and crankshafts. The ability to cast large, complex shapes makes it ideal for producing these high-strength components, which are essential in engine performance.

2. Aerospace Industry

Cast 4140 steel is used in aerospace for landing gear parts and structural components. These parts require high strength and toughness to withstand the extreme conditions during flight and landing.

3. Heavy Machinery

For heavy machinery, cast 4140 steel is ideal for hydraulic components and machine frames. Its high fatigue resistance and strength make it suitable for use in demanding environments where durability is key.

4. Oil and Gas

In the oil and gas industry, cast 4140 steel is used for drill rods, downhole tools, and valves. The material’s ability to resist high pressure and wear makes it perfect for equipment that operates in harsh, high-pressure environments.

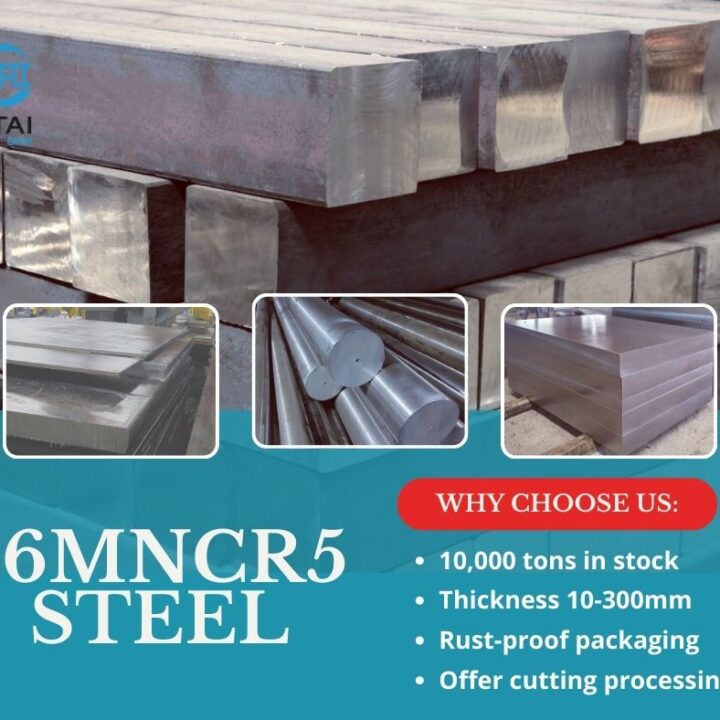

🏆 Why Choose Otai Special Steel for Cast 4140 Steel?

Otai Special Steel offers cast 4140 steel with several key benefits:

-

Large Inventory: We maintain over 10,000 tons of steel in stock, ensuring prompt delivery to meet your needs.

-

Customization: We offer cutting, heat treatment, and surface finishing services to tailor the material to your specifications.

-

Quality Assurance: Each batch of cast 4140 steel undergoes rigorous quality control to ensure that it meets your exact standards.

-

Global Expertise: With years of experience in supplying high-performance steel, we provide reliable materials to clients worldwide.

❓ FAQ: Common Questions About Cast 4140 Steel

Q1: How does cast 4140 steel compare to forged 4140 steel?

A1: Both cast 4140 steel and forged 4140 steel offer similar mechanical properties. However, cast 4140 steel is ideal for producing large and complex parts at a lower cost, whereas forged 4140 steel provides higher toughness for parts requiring maximum strength.

Q2: Can cast 4140 steel be heat-treated?

A2: Yes, cast 4140 steel can undergo heat treatment processes like tempering and quenching to improve its hardness and wear resistance. Heat treatment enhances its performance in high-stress and high-wear applications.

Q3: Is cast 4140 steel suitable for high-temperature applications?

A3: Yes, cast 4140 steel can handle high temperatures, but it’s essential to consider heat treatment and proper design to maintain its strength and durability in extreme conditions.