AISI 4140 Steel Composition – Key Elements and Their Role in Performance

AISI 4140 Steel Composition – Key Elements and Their Role in Performance

Among medium-carbon alloy steels, AISI 4140 steel composition makes it one of the most versatile and reliable grades for engineering applications. Known as a chromium-molybdenum steel, it balances strength, toughness, and wear resistance. But what makes it special lies in the exact combination of elements in its composition.

This article explores the aisi 4140 chemical composition, explains the role of each element, and links the chemistry to real-world performance.

🌟 Why Study the Composition of AISI 4140 Steel?

When engineers select a material, they don’t just look at hardness or tensile strength. They also analyze the chemistry. The aisi 4140 alloy steel composition determines its ability to withstand heat treatment, resist fatigue, and maintain toughness. For buyers, knowing the composition ensures compatibility with project requirements and international standards.

🔬 AISI 4140 Steel Composition Table

Here’s the standard aisi 4140 steel composition table (ASTM/SAE):

| Element | Percentage (%) |

|---|---|

| Carbon (C) | 0.38 – 0.43 |

| Manganese (Mn) | 0.75 – 1.00 |

| Chromium (Cr) | 0.80 – 1.10 |

| Molybdenum (Mo) | 0.15 – 0.25 |

| Silicon (Si) | 0.15 – 0.30 |

| Phosphorus (P) | ≤ 0.035 |

| Sulfur (S) | ≤ 0.040 |

This combination creates a balance between aisi 4140 steel elements that influence hardness, wear resistance, and toughness.

🧪 Element-by-Element Breakdown

Let’s look at how each part of the aisi 4140 chemical composition contributes to its performance:

-

Carbon (0.38–0.43%) – Provides core hardness and strength. Medium carbon allows for a balance of toughness and machinability.

-

Chromium (0.80–1.10%) – Enhances wear resistance, improves hardenability, and increases corrosion resistance slightly.

-

Molybdenum (0.15–0.25%) – Adds creep strength, prevents brittleness, and ensures stability during high-temperature service.

-

Manganese (0.75–1.00%) – Improves hardenability and tensile strength while also helping deoxidize the steel.

-

Silicon (0.15–0.30%) – Strengthens the ferrite phase and helps improve toughness.

-

Phosphorus & Sulfur (low levels) – Controlled to prevent brittleness and maintain toughness.

This chemical mix explains why aisi 4140 steel carbon content alone doesn’t tell the full story—chromium and molybdenum make it unique.

⚙️ Composition vs Properties

The link between aisi 4140 composition vs properties is direct:

| Property | Influence of Composition |

|---|---|

| Strength | Carbon, Mn, Cr, Mo |

| Hardenability | Chromium, Molybdenum |

| Wear Resistance | Chromium, Carbon |

| Toughness | Balanced C, low P/S |

| High-Temperature Performance | Molybdenum |

This synergy gives engineers confidence in using 4140 for demanding parts.

🔥 Heat Treatment and Composition

The aisi 4140 steel heat treatment and composition relationship is critical.

-

Annealing (soft state) – Carbon level allows machinability, hardness ~197 HB.

-

Quenching & Tempering – Chromium and molybdenum ensure deep hardening; hardness ranges from 28 to 60 HRC.

-

Nitriding – Surface enriched with nitrogen creates wear resistance (55–60 HRC surface).

Because of its aisi 4140 steel chromium molybdenum content, this grade responds better to heat treatment than plain carbon steels.

📊 Comparison with Other Alloy Steels

When comparing aisi 4140 alloy steel composition with similar grades:

| Grade | Carbon % | Cr % | Mo % | Notes |

|---|---|---|---|---|

| AISI 4140 | 0.38–0.43 | 0.80–1.10 | 0.15–0.25 | Balanced properties |

| AISI 4340 | 0.38–0.43 | 0.70–0.90 | 0.20–0.30 + Ni (1.65–2.00) | Higher toughness |

| AISI 1045 | 0.43–0.50 | – | – | Plain carbon steel, lower hardenability |

| 42CrMo4 (DIN) | Similar to 4140 | Similar | Similar | European equivalent |

This shows how chemistry defines different mechanical behaviors.

🛠️ Applications Linked to Composition

The aisi 4140 steel composition makes it suitable for:

-

Automotive parts: gears, crankshafts, axles.

-

Oil & gas: drill collars, tool joints, downhole tools.

-

Aerospace: landing gear, high-strength bolts.

-

General machinery: shafts, spindles, couplings.

Each application benefits from the steel’s unique chemistry that allows strength without brittleness.

🌍 Company Advantages – Why Choose Otai Special Steel?

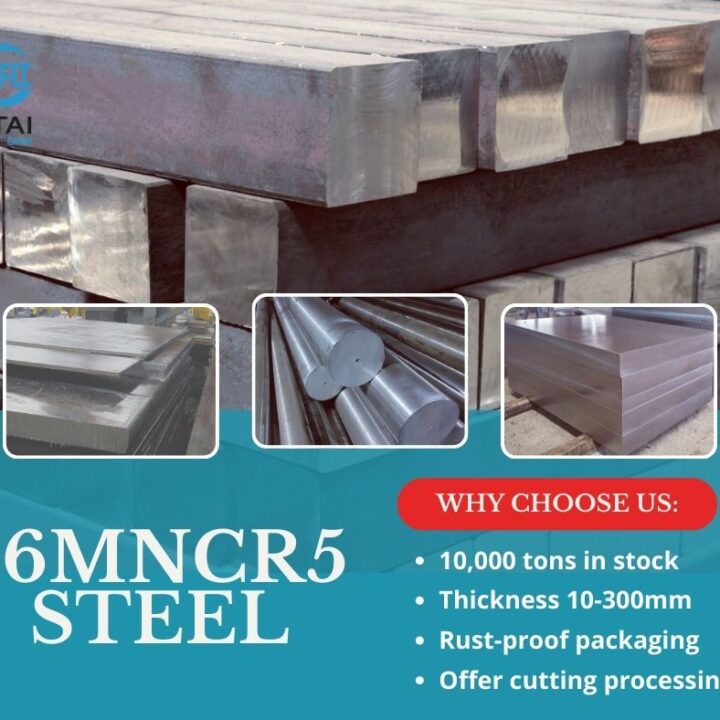

At Otai Special Steel, we specialize in supplying AISI 4140 alloy steel composition in plate, bar, and forged forms.

-

📦 Large Inventory – Over 10,000 tons of alloy steels in stock.

-

🏭 Processing Services – Cutting, heat treatment, machining.

-

🔍 Quality Control – UT testing, chemical analysis, third-party inspections.

-

🌐 Global Network – Exporting to 50+ countries with experience in international standards.

-

💰 Cost Advantage – Competitive pricing without compromising quality.

❓ FAQ

Q1: What is the carbon content of AISI 4140 steel?

A: About 0.38–0.43%, making it a medium-carbon steel.

Q2: Why is chromium important in AISI 4140 composition?

A: It increases hardenability and wear resistance, making it superior to plain carbon steels.

Q3: Can composition affect weldability?

A: Yes, higher carbon and alloy content reduce weldability, so preheating is recommended.

Q4: Is AISI 4140 equivalent to 42CrMo4?

A: Yes, they have nearly identical compositions and performance.

Q5: How does composition affect heat treatment response?

A: Chromium and molybdenum allow deep hardening and make quenching & tempering highly effective.