Bending 4140 Steel: Practical Guide for Safe and Effective Forming

If you work in fabrication, machining, or heavy equipment repair, chances are you’ve come across bending 4140 steel at some point. This high-strength chromium-molybdenum alloy steel is famous for its toughness and wear resistance—but those same qualities can make forming it a real challenge.

In this guide, we’ll break down how to bend 4140 steel without cracking, losing strength, or ruining your part. We’ll look at cold bending 4140 steel, hot forming techniques, correct bend radius guidelines, post-bend heat treatments, and real-world examples from industry.

🌟 Why Bending 4140 Steel Is Different from Mild Steel

4140 steel is far stronger than mild carbon steels like 1018 or 1045. It has higher tensile and yield strength, which makes it resist deformation—but also means that forcing it to bend creates higher stress concentrations.

The difficulty depends heavily on its condition:

| Condition | Ductility | Bendability | Notes |

|---|---|---|---|

| Annealed | High | Easy to bend cold | Best for cold bending 4140 steel |

| Normalized | Moderate | Needs larger bend radius | Slightly stiffer than annealed |

| Quenched & Tempered (Q&T) | Low | Hot bending recommended | High risk of cracking if bent cold |

| Nitrided / Surface Hardened | Very low | Not recommended | Brittle surface layer fractures easily |

💡 In short: the harder the steel, the less you should attempt to bend it cold.

🔥 Cold vs Hot Bending – Which One Should You Use?

Choosing between hot bending 4140 steel and cold forming depends on the part’s condition and final use.

| Method | Recommended Condition | Risk Level | Temperature Range | Notes |

|---|---|---|---|---|

| Cold bending 4140 steel | Annealed or normalized | ⚠️ Moderate | Ambient | Requires large bend radius, avoid sharp bends |

| Hot bending 4140 steel | Q&T or hardened | ✅ Low | 850–900°C (1560–1650°F) | Allows tighter bends without cracking |

| Warm bending | As-rolled / normalized | ⚠️ Medium | 500–650°C (930–1200°F) | Improves ductility slightly, but not as safe as full hot bending |

📐 Minimum Bend Radius – Avoid Cracks Before They Happen

The minimum bend radius for 4140 steel depends on hardness, thickness, and forming temperature. Using too small a radius is the #1 cause of cracking during bending.

| Condition | Minimum Bend Radius (× Thickness) | Comments |

|---|---|---|

| Annealed | 2.5–3× | Best option for cold bending |

| Normalized | 3–4× | Slightly stiffer |

| Q&T (28–32 HRC) | 4–6× | Only hot bend |

| Nitrided | Avoid bending | Surface layer too brittle |

💡 Tip: For parts thicker than 25 mm, increase the radius by at least 25% to reduce stress.

⚙️ Heat Treatment After Bending – Keep the Strength

Bending changes the steel’s internal grain structure and introduces residual stresses. Without proper heat treatment afterward, bent 4140 steel can have reduced fatigue strength.

Post-bend heat treatment steps:

-

Stress relief – Heat to ~600°C (1110°F) and hold for 1 hour per inch thickness.

-

Re-tempering – If the steel was quenched and tempered before bending, temper again to restore toughness.

-

Inspection – Perform ultrasonic or magnetic particle testing to check for hidden cracks.

🧠 Real-World Case Study – Offshore Drilling Components

One of our oil & gas clients in Singapore needed custom 4140 Q&T brackets bent to a precise angle for drilling rigs. Their first attempt at cold bending failed—micro-cracks formed along the bend line.

We recommended hot bending 4140 steel at 870°C, followed by stress relief and re-tempering. The result: zero failures in over 1,000 parts, each passing ultrasonic inspection.

⚠️ Common Mistakes to Avoid

-

Using too tight a bend radius – Always follow radius guidelines.

-

Skipping preheat for hardened steel – Leads to cracking.

-

Bending nitrided 4140 steel – The brittle layer will fracture.

-

Skipping stress relief – Residual stresses reduce fatigue life.

-

Wrong tooling – Use tooling matched to the bend radius and thickness.

🔍 Comparing Bending 4140 Steel vs Other Steels

| Steel Type | Ease of Bending | After Hardening | Notes |

|---|---|---|---|

| Mild Steel (1018) | ✅ Easy | ❌ Loses strength | Best for prototypes and simple parts |

| 1045 Carbon Steel | ⚠️ Moderate | ⚠️ Moderate cracking risk | Needs larger bend radius |

| 4140 Alloy Steel | ⚠️ Moderate | ❌ Hot bending only | Stronger but less ductile |

| 4340 Alloy Steel | ❌ Difficult | ❌ Requires very high heat | Higher strength, lower ductility |

🛠️ Advanced Tips for Success in Bending 4140 Steel

-

Preheat thicker sections before bending to improve ductility.

-

Use a press brake with precise control for uniform bends.

-

Consider annealing before bending if you start with hardened steel.

-

Plan for springback—4140 steel will “spring” more than mild steel after bending.

-

For parts in fatigue service, always combine bending 4140 steel with stress relief and inspection.

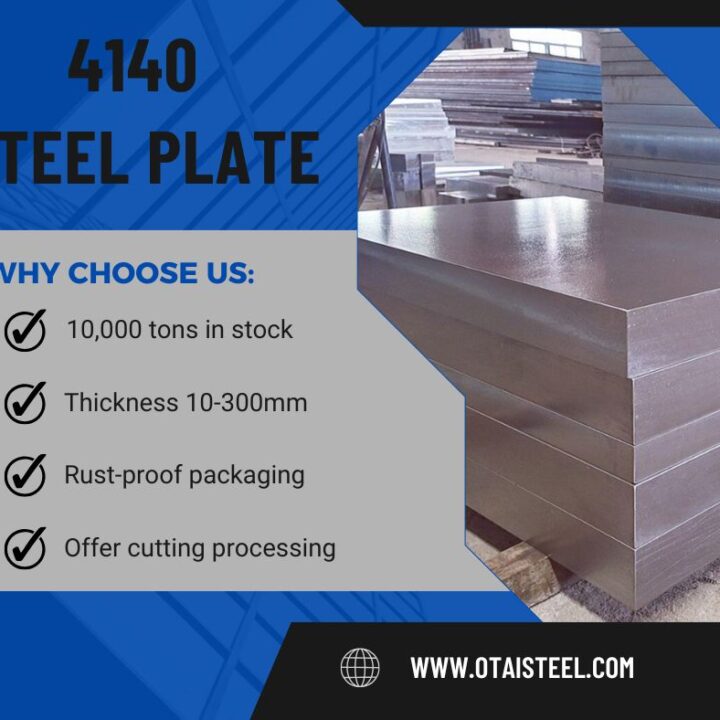

🏭 Company Advantages – Why Choose Otai Steel

At Otai Special Steel, we don’t just supply 4140—we help you bend it right.

-

✅ 10,000+ tons of 4140 in stock (6mm–300mm thick)

-

✅ Supply in annealed, normalized, or Q&T condition

-

✅ Cut-to-size service for bending jobs

-

✅ Technical guidance on bending 4140 steel without cracking

-

✅ Optional heat treatment after forming

-

✅ SGS/BV inspection available for export orders

-

✅ Trusted by global brands like Thyssenkrupp, Borealis, and Schlumberger

📧 Contact us: jack@otaisteel.com

📱 WhatsApp: +8676923190193

❓ FAQ

Q1: Can you bend quenched and tempered 4140 steel?

Yes, but it must be hot bent, followed by re-tempering to restore mechanical properties.

Q2: What is the best temperature for bending 4140 steel?

Around 850–900°C (1560–1650°F) for hardened or Q&T conditions.

Q3: Can you cold bend 4140 steel?

Yes, but only if annealed or normalized, and with the correct bend radius.

Q4: Do I need heat treatment after bending?

For critical components, yes—stress relief or tempering ensures long-term performance.

Q5: Can you bend nitrided 4140?

Not recommended—the surface will crack.