What’s the Carbon Content in 4140 Steel

What’s the Carbon Content in 4140 Steel

You’ve probably heard a lot about 4140 steel—it’s a go-to material in industries where strength and toughness are a must. But here’s the burning question: What’s the deal with carbon in 4140 steel? Why does it matter so much? 🤷♂️ Well, let’s break it down and find out how this small percentage of carbon can make a huge difference! 💥

🧐 So, What’s the Carbon Content in 4140 Steel?

Let’s cut to the chase: 4140 steel contains between 0.38% and 0.43% carbon. Sounds pretty specific, right? But here’s the kicker—this small amount of carbon is what gives 4140 the perfect balance of strength, toughness, and machinability. 😎

Too much carbon, and the steel becomes brittle. Too little, and it’s not strong enough. But 4140 steel? It’s just right—giving you hardness when you need it, and toughness to handle the pressure. 💪

🔥 Why Does Carbon Matter in 4140 Steel?

Think of carbon like the spice in a recipe—too much or too little can mess things up, but just the right amount brings everything together. 🍲 In 4140 steel, carbon plays a key role in giving the material strength and hardness, while still keeping it tough enough to avoid cracking under stress. 💥

Let’s break down how carbon affects 4140 steel:

| Feature | Low Carbon Steel | 4140 Steel | High Carbon Steel |

|---|---|---|---|

| Carbon Content | < 0.30% | 0.38% – 0.43% | > 0.50% |

| Hardness | Low | Medium (28-32 HRC) | High |

| Strength | Low | High (850-1000 MPa) | Very High |

| Toughness | High | Good to Moderate | Low |

| Machinability | Very Easy | Moderate | Difficult |

- Strength: With its 0.38%-0.43% carbon, 4140 steel is strong enough to withstand heavy-duty tasks like automotive parts, gears, and machinery components. It’s like the unsung hero that holds everything together in the toughest conditions. ⚙️

- Hardness: After heat treatment, 4140 steel reaches 28-32 HRC, making it resistant to wear but not overly brittle—so it can stand up to abrasion without cracking under pressure. 🔧

- Toughness: It’s tough, but not indestructible. 4140 can handle the shock and impact that come with high-stress situations, making it ideal for parts like suspension components and drivetrain parts in the automotive industry. 🚗💨

- Machinability: Here’s the best part—4140 steel is actually pretty easy to machine compared to some other alloys. It’s tough but still manageable with the right tools, making it great for custom parts and precision machining. 🔨

✨ Heat Treatment Magic: How Carbon Changes Everything

Here’s where the real transformation happens. When you add heat treatment to the mix, carbon content in 4140 steel takes it to the next level. 💥

- Quenching: The steel is heated to a high temperature and then cooled rapidly—this is where the carbon really shines. The steel becomes harder and more resistant to wear. ⚡

- Tempering: After quenching, 4140 steel is reheated to a lower temperature to reduce brittleness. This ensures the steel is strong but still tough enough to absorb shock without cracking. 💎

This is why 4140 is used in high-performance components that need to withstand the toughest conditions, like gears, axles, and drill collars in industries like automotive and oil & gas. 🌍

🤔 What Happens If You Add More Carbon?

Let’s talk about more carbon for a second—because, yes, more is not always better. Here’s what happens:

- Too much carbon: The steel gets harder, but it also becomes more brittle and prone to cracking under impact. That’s why high-carbon steels are great for cutting tools or blades but not ideal for parts that undergo a lot of stress or impact. ⚔️

- Too little carbon: The steel becomes softer and lacks the strength needed for demanding applications. 😕

4140 steel has the perfect amount of carbon, making it a goldilocks steel—not too hard, not too soft, just right for high-performance parts that need to last. 🎯

🌟 Where Does 4140 Steel Really Shine?

Thanks to its carbon content and versatility, 4140 steel is used across a wide range of industries. Here are just a few places where it truly shines:

| Industry | Applications |

|---|---|

| Automotive | Drive shafts, suspension components, gears |

| Aerospace | Aircraft parts, structural components |

| Oil & Gas | Drill collars, pump shafts, tool joints |

| Industrial Machinery | Hydraulic cylinders, machine tool components |

| Construction | Heavy-duty machinery, lifting equipment |

In the automotive world, 4140 steel is used for parts like drive shafts, gears, and axles that need to stand up to high levels of stress and wear. It’s like the unsung hero in your car’s drivetrain, helping you get from A to B without fail. 🚙💨

In oil and gas, where equipment is subjected to extreme conditions, 4140 steel is used in drill collars and tool joints. It’s tough enough to handle the intense pressures and abrasive materials encountered deep underground. ⛏️

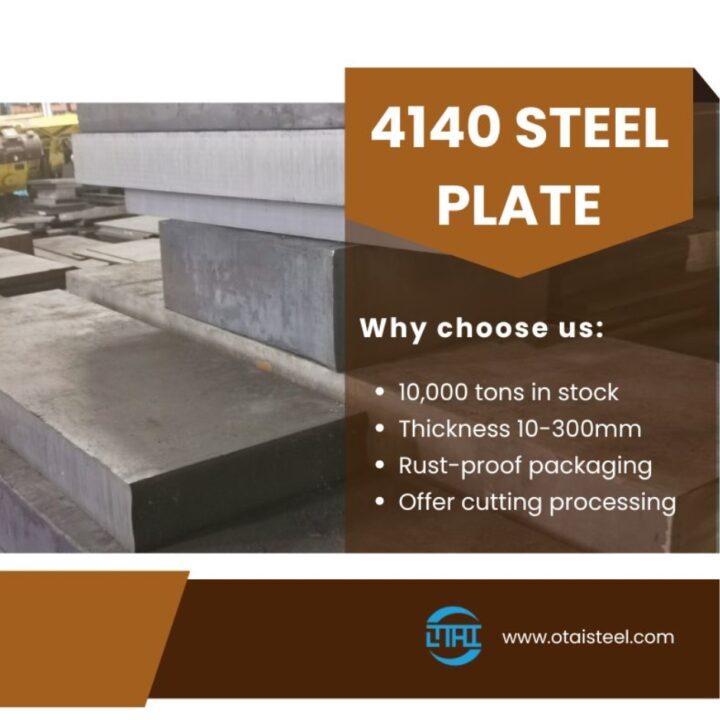

😎 Why Choose Otai Steel for Your 4140 Steel Needs?

When it comes to 4140 steel, you want a supplier you can trust to deliver high-quality, reliable material that meets your exact needs. Here’s why Otai Special Steel is the best choice for your project:

- Massive Stock: Over 10,000 tons of alloy steel in inventory—we’ve got what you need. 📦

- Custom Sizes: Cut-to-size services available, tailored to your specific project requirements. 📏

- Precision Heat Treatment: We provide custom heat treatment for enhanced steel performance. 🔥

- Top-Notch Testing: UT testing and chemical composition testing ensure high-quality steel every time. 🧪

- Fast Global Shipping: We ship worldwide with third-party inspections like SGS for peace of mind. ✈️

- 25+ Years of Experience: Trusted by leading companies like Thyssenkrupp, Borealis, and Schlumberger. 🌏

At Otai, we don’t just supply steel; we provide solutions. Whether you need 4140 steel for a small project or large-scale production, we’re here to support you every step of the way. 😎

📧 Contact us for a quote: jack@otaisteel.com

📱 WhatsApp: +8676923190193

💬 FAQs – Carbon Content in 4140 Steel

1. What is the carbon content in 4140 steel?

4140 steel contains 0.38% to 0.43% carbon, giving it the perfect balance of strength, toughness, and machinability. 🔧

2. How does carbon affect 4140 steel?

Carbon enhances 4140 steel’s strength, hardness, and wear resistance, while ensuring it remains tough enough for high-stress applications. 💪

3. Is 4140 steel difficult to machine?

Not at all! While it’s tougher than low-carbon steels, 4140 steel is still relatively easy to machine, especially with proper heat treatment. 🛠️

4. Can you provide 4140 steel in custom sizes?

Absolutely! We offer cut-to-size, heat-treated, and machined 4140 steel to meet your exact specifications. 📏