Is 4140 Steel Stainless?

Is 4140 Steel Stainless?

When engineers, buyers, or manufacturers hear the question is 4140 steel stainless, they are usually trying to determine whether this widely used alloy steel offers the same corrosion resistance as stainless steel grades. The short answer is: 4140 is not stainless steel. It is a chromium-molybdenum alloy steel known for toughness, hardness, and strength, but it does not have the high chromium content that defines stainless steels.

Let’s dive deeper to understand the differences, properties, and practical implications for industries that rely on 4140 steel.

✨ What Defines Stainless Steel?

Stainless steel is categorized by its minimum chromium content of about 10.5%, which provides a protective passive layer on the surface, preventing rust and corrosion. Many stainless steels also contain nickel, molybdenum, and other alloying elements to enhance resistance in harsh environments.

Common stainless steel grades include:

-

304 Stainless Steel – general purpose, widely used in food processing and architecture.

-

316 Stainless Steel – marine-grade, offering superior resistance to chloride corrosion.

-

410 Stainless Steel – martensitic, offering moderate corrosion resistance and hardness.

In contrast, 4140 steel only contains about 0.8–1.1% chromium and lacks sufficient levels to create stainless behavior.

🔎 Chemical Composition of 4140 Steel

| Element | Percentage (%) |

|---|---|

| Carbon (C) | 0.38 – 0.43 |

| Chromium (Cr) | 0.8 – 1.1 |

| Molybdenum (Mo) | 0.15 – 0.25 |

| Manganese (Mn) | 0.75 – 1.0 |

| Silicon (Si) | 0.15 – 0.3 |

| Iron (Fe) | Balance |

From this chart, you can see why asking is 4140 steel stainless is a common confusion: while it does contain chromium, the percentage is not nearly high enough to classify it as stainless steel.

⚙️ Key Properties of 4140 Steel

4140 steel is valued not for corrosion resistance, but for strength and toughness. Its main properties include:

-

High strength-to-weight ratio – suitable for heavy-duty applications.

-

Excellent hardenability – responds well to quenching and tempering.

-

Good wear resistance – useful in tooling and machinery parts.

-

Moderate corrosion resistance – better than plain carbon steel, but inferior to stainless steels.

🏭 Industrial Applications of 4140 Steel

Despite not being stainless, 4140 steel remains one of the most popular alloy steels for critical components. Some common applications include:

-

Gears and shafts in automotive and industrial machinery.

-

Oilfield equipment like drill collars and tool joints.

-

Aerospace parts requiring strength and fatigue resistance.

-

High-strength bolts, fasteners, and connecting rods.

These uses highlight that asking is 4140 steel stainless is less important than recognizing where 4140 excels compared to stainless.

🔧 Comparing 4140 Steel and Stainless Steel

| Feature | 4140 Steel | Stainless Steel (304/316) |

|---|---|---|

| Chromium Content | 0.8 – 1.1% | 10.5% minimum, up to 20%+ |

| Corrosion Resistance | Moderate | Excellent |

| Mechanical Strength | Very high | Moderate to high |

| Weldability | Requires preheat/post-weld | Easier (depending on grade) |

| Cost | Lower than stainless | Higher due to alloying elements |

This comparison helps explain why industries often select 4140 steel over stainless when mechanical strength is prioritized over corrosion resistance.

🛡️ Protecting 4140 Steel from Corrosion

Since the answer to is 4140 steel stainless is no, proper protection is crucial. Common methods include:

-

Heat treatments such as quenching and tempering for surface hardness.

-

Protective coatings like zinc plating, black oxide, or nitriding.

-

Lubrication and maintenance in high-friction environments.

-

Environmental control by avoiding prolonged exposure to moisture or chemicals.

🌍 Why 4140 Steel Is Still Widely Used

Even though it lacks stainless properties, 4140 steel is trusted worldwide because:

-

It offers superior mechanical performance under stress.

-

It can be heat treated to achieve tailored hardness levels.

-

It is versatile in machining, forging, and welding (with proper procedures).

-

It provides cost savings compared to stainless alternatives.

So, when customers ask is 4140 steel stainless, the best answer is: it is not stainless, but it is a high-strength alloy steel that fulfills demanding structural needs.

🌟 Company Advantages – Why Choose Otai Special Steel

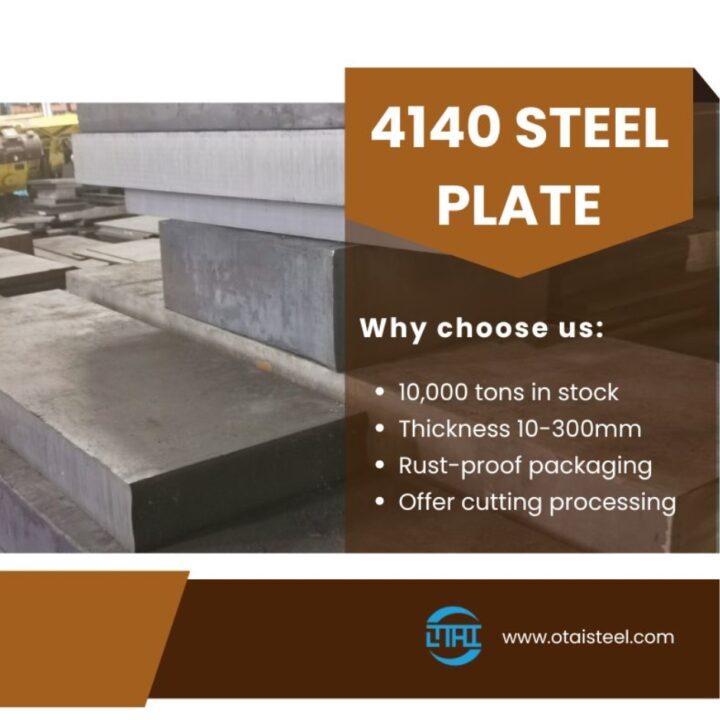

At Otai Special Steel, we specialize in supplying 4140 alloy steel in plates, bars, and customized shapes. Here’s why global customers trust us:

-

📦 Huge Inventory – Over 10,000 tons in stock, ready for immediate delivery.

-

🛠️ Custom Processing – Cutting, heat treatment, and surface finishing tailored to your needs.

-

🔬 Quality Assurance – Ultrasonic testing (UT), chemical analysis, and SGS inspection available.

-

🌍 Global Reach – Experience supplying world-class companies like Thyssenkrupp and Schlumberger.

-

💰 Competitive Pricing – Factory-direct supply for cost-effective solutions.

Whether you need small quantities or bulk orders, Otai is your reliable partner for 4140 alloy steel supply.

❓ FAQ

Q1: Is 4140 steel stainless?

No. It contains chromium, but not enough to classify it as stainless steel.

Q2: Can 4140 steel resist corrosion?

It has moderate resistance, better than plain carbon steel, but much lower than stainless steel. Protective coatings are recommended.

Q3: When should I choose stainless over 4140 steel?

If corrosion resistance is critical (e.g., food, marine, or medical industries), stainless steel is the better choice.

Q4: What’s the biggest advantage of 4140 steel?

Its combination of toughness, hardness, and strength makes it ideal for gears, shafts, and heavy-duty parts.

Q5: Can 4140 steel be heat treated?

Yes. It responds very well to heat treatments like quenching and tempering, improving hardness and mechanical performance.