Names for 4140 Steel: Why It Matters in Global Sourcing

Names for 4140 Steel: Why It Matters in Global Sourcing

When it comes to buying or specifying 4140 steel, one thing often confuses buyers and engineers: it doesn’t always go by the same name. Depending on the country, standard, or industry, 4140 steel might have a completely different designation. If you don’t know these equivalents, you risk delays, wrong materials, or costly replacements. Let’s break down all the other names for 4140 steel and see why understanding them is key to global sourcing.

🌍 Why 4140 Steel Has So Many Names

The reason is simple—different countries and standards organizations have their own classification systems. Even though the chemical composition and mechanical properties are nearly identical, the naming format changes.

For example:

-

In the United States, the SAE/AISI system calls it AISI 4140.

-

In Europe, it might be listed under an EN number, such as 42CrMo4.

-

In Germany, you might see the Werkstoff number 1.7225.

If you’re sourcing materials internationally, knowing these names helps you match specs without relying solely on “4140” in a quotation.

📋 Common International Equivalents for 4140 Steel

| Country/Standard | Common Name | Standard Reference | Notes |

|---|---|---|---|

| USA (AISI/SAE) | AISI 4140 | SAE J404 | Widely used in North America |

| Europe (EN) | 42CrMo4 | EN 10083-3 | Common in EU markets |

| Germany (DIN/Werkstoff) | 1.7225 | DIN 17200 | Popular in German engineering |

| Japan (JIS) | SCM440 | JIS G4105 | Used in automotive and machinery |

| China (GB) | 42CrMo | GB/T 3077 | Standard in Chinese market |

| UK (BS) | 708M40 | BS 970 | Common in UK heavy industry |

| France (AFNOR) | 42CD4 | NF A35-552 | French steel designation |

| Russia (GOST) | 38KhM | GOST 4543 | Used in aerospace & defense |

These names all refer to steels with similar chemical compositions—typically containing 0.38–0.43% carbon, 0.75–1.00% chromium, and 0.15–0.25% molybdenum—making them equivalent in most applications.

🛠️ Industries That Rely on 4140 Steel Equivalents

Understanding alternative names isn’t just for steel traders—it’s crucial for manufacturers and engineers in:

-

Oil & Gas (drill collars, tool joints, high-strength shafts)

-

Automotive (gears, crankshafts, axles)

-

Aerospace (landing gear components, structural fittings)

-

Heavy Equipment (mining machinery, construction tools)

If your supplier lists SCM440 but your blueprint says AISI 4140, knowing they’re equivalents saves you weeks of back-and-forth emails.

📌 How to Confirm You’re Getting the Right Steel

Even if the name matches, it’s best to verify the chemical composition and mechanical properties before purchase. The table below shows typical values for 4140 steel and its equivalents:

| Property | Typical Value (Quenched & Tempered) |

|---|---|

| Tensile Strength | 850–1000 MPa |

| Yield Strength | 655 MPa |

| Hardness | 28–32 HRC |

| Elongation | 17–21% |

| Impact Toughness (Charpy V-notch) | ≥ 35 J |

Cross-referencing these values with your supplier’s mill test certificate ensures no surprises after delivery.

💡 Pro Tips for Buyers and Engineers

-

Always include equivalents in RFQs (Request for Quotation).

-

Specify standards (AISI, EN, DIN, JIS, etc.) rather than just “4140.”

-

Ask for MTC (Mill Test Certificate) to confirm properties.

-

Verify heat treatment—mechanical performance can vary widely.

-

Work with distributors experienced in international steel supply.

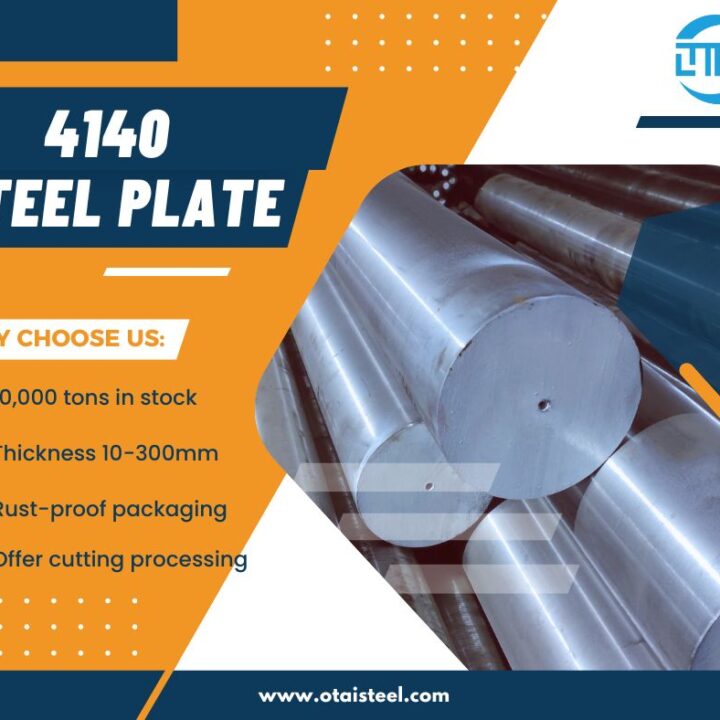

🏆 Why Choose Otai Special Steel

At Otai Special Steel, we’ve been supplying 4140 steel and its equivalents for over 20 years. With more than 10,000 tons in stock, we offer:

-

✅ Complete range of grades: AISI 4140, 42CrMo4, SCM440, 1.7225, and more

-

✅ Precision cutting services from 6mm to 300mm thickness

-

✅ Heat treatment options: annealing, quenching, and tempering

-

✅ Quality control with UT testing, chemical analysis, and third-party inspection (SGS)

-

✅ Global shipping and competitive pricing

Whether you’re sourcing for oil rigs, aerospace, or heavy machinery, we make sure you get the exact grade you need—on time and to spec.

❓ FAQ

Q1: Are all these equivalent grades exactly the same?

Not exactly—minor differences in composition or mechanical properties may exist, but they are usually interchangeable for most engineering applications.

Q2: If I specify 42CrMo4, can my supplier send SCM440 instead?

Yes, in most cases, as long as mechanical properties meet your design requirements and it passes quality tests.

Q3: Is 4140 steel considered an alloy steel?

Yes, it’s a chromium-molybdenum alloy steel.

Q4: How do I ensure correct heat treatment?

Request heat-treatment certificates and verify hardness and strength after processing.