Steel Similar to 4140: Exploring Alternative Alloys for Your Toughest Applications

Steel Similar to 4140: Exploring Alternative Alloys for Your Toughest Applications

4140 steel is known for its excellent balance of strength, toughness, and wear resistance, making it a popular choice in industries like automotive, aerospace, and manufacturing. But what if you need a steel with similar properties but with slight variations to meet specific application requirements? In this article, we’ll explore some steel alloys similar to 4140 that provide comparable or enhanced properties, making them ideal alternatives for demanding industrial uses.

🌟 What Makes 4140 Steel Special?

Before diving into its alternatives, it’s essential to understand what makes 4140 steel unique. As an alloy steel, it contains:

| Element | Percentage |

|---|---|

| Carbon (C) | 0.38–0.43% |

| Chromium (Cr) | 0.80–1.10% |

| Molybdenum (Mo) | 0.15–0.25% |

| Manganese (Mn) | 0.60–0.90% |

| Silicon (Si) | 0.20–0.35% |

These elements provide 4140 steel with the ability to maintain high tensile strength, impact resistance, and fatigue resistance, even under harsh conditions. It also responds well to heat treatment, offering versatility in applications like gears, axles, crankshafts, and more.

But what if you need a steel that is almost as strong or offers specific enhancements, such as higher corrosion resistance or improved hardenability? Let’s look at some alternatives that share similar characteristics with 4140 steel.

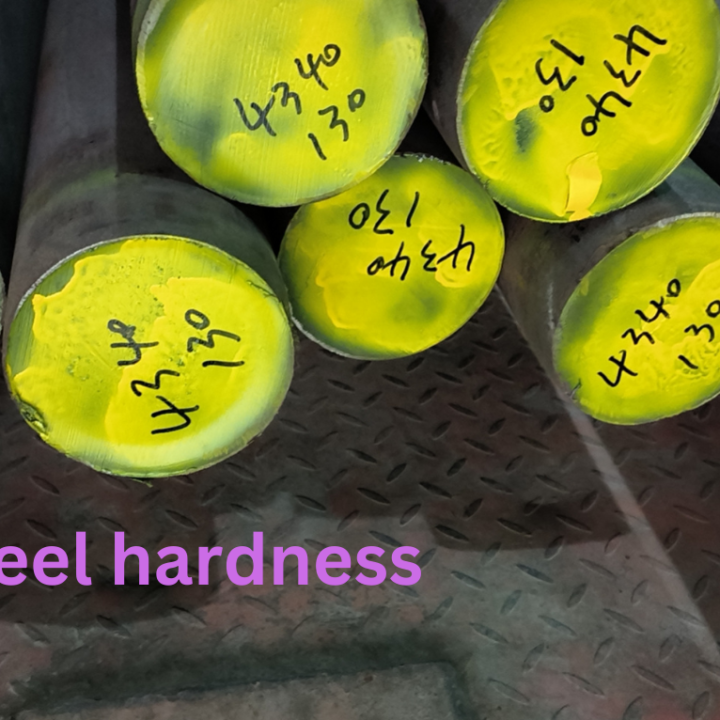

🔧 1. 4340 Steel: A Stronger Alternative

4340 steel is often considered one of the closest alternatives to 4140 steel. It shares many of the same alloying elements but with higher nickel content, which increases its toughness and strength, especially at low temperatures.

Key Features of 4340 Steel:

| Property | 4340 Steel |

|---|---|

| Tensile Strength | 1080–1200 MPa |

| Nickel Content | 1.65–2.00% |

| Impact Toughness | Very high |

| Fatigue Resistance | Excellent |

4340 steel is commonly used in industries where superior toughness and fatigue resistance are critical, such as aerospace, automotive, and marine applications.

🔨 2. 4130 Steel: A More Cost-Effective Choice

While 4130 steel is slightly lower in strength compared to 4140 steel, it is an affordable alternative that still offers good toughness, weldability, and machinability. The lower carbon content (0.28–0.33%) gives it better weldability and lower hardness, making it an excellent choice for projects where welding is necessary.

Key Features of 4130 Steel:

| Property | 4130 Steel |

|---|---|

| Tensile Strength | 700–900 MPa |

| Carbon Content | 0.28–0.33% |

| Weldability | Excellent |

| Cost | More affordable |

4130 steel is widely used in aircraft frames, racing car chassis, and bicycles—where strength is important, but weldability and cost play a larger role.

⚙️ 3. 8620 Steel: Ideal for Gears and Shafts

8620 steel is another close alternative to 4140 steel, particularly when dealing with gears, shafts, and crankshafts that require high toughness and wear resistance. The key difference is in the nickel content, which provides improved hardenability.

Key Features of 8620 Steel:

| Property | 8620 Steel |

|---|---|

| Tensile Strength | 950–1100 MPa |

| Nickel Content | 0.30–0.60% |

| Case Hardening | Excellent |

| Wear Resistance | High |

With its strong case-hardened surface, 8620 steel is a popular choice for manufacturing gears and machine components that undergo high levels of wear but do not require through-hardening.

🛠️ 4. 4150 Steel: A High-Strength Alternative

4150 steel is very similar to 4140 steel, but it contains slightly higher carbon content and can be alloyed with vanadium to further increase its strength and wear resistance. As a result, 4150 steel often has higher tensile strength and hardness, making it suitable for heavy-duty applications.

Key Features of 4150 Steel:

| Property | 4150 Steel |

|---|---|

| Tensile Strength | 1000–1200 MPa |

| Carbon Content | 0.48–0.53% |

| Vanadium Content | 0.10–0.20% |

| Wear Resistance | Very high |

4150 steel is a great choice for military, construction, and oilfield equipment where extreme strength and wear resistance are required.

🌍 5. 4142 Steel: Strong and Tough

4142 steel is another strong alternative that offers higher strength and wear resistance compared to 4140 steel. It also has good machinability and weldability, making it ideal for applications requiring a combination of both strength and ease of processing.

Key Features of 4142 Steel:

| Property | 4142 Steel |

|---|---|

| Tensile Strength | 1000–1100 MPa |

| Carbon Content | 0.42–0.50% |

| Machinability | Good |

| Weldability | Good |

4142 steel works well in automotive, manufacturing, and hydraulic components where a higher strength-to-weight ratio is needed.

🏗️ Which Steel Should You Choose?

When selecting a steel similar to 4140, the choice ultimately depends on your application’s specific needs:

| Steel | Key Strength | Ideal Use Case |

|---|---|---|

| 4340 Steel | Higher toughness and fatigue resistance | Aerospace, automotive, heavy-duty machinery |

| 4130 Steel | Lower strength, better weldability | Aircraft frames, racing car chassis, bicycles |

| 8620 Steel | Excellent case hardening properties | Gears, shafts, pistons |

| 4150 Steel | Higher strength and wear resistance | Military vehicles, construction, oilfield equipment |

| 4142 Steel | Strong and tough with good machinability | Automotive, hydraulic components |

🏆 Why Choose Otai Special Steel for Your Steel Needs?

At Otai Special Steel, we specialize in providing high-quality alloy steels like 4140 and its alternatives. Here’s why you should consider working with us:

-

Large Inventory: We maintain a large stock of 4140 steel and similar alloys, ready to meet your specific requirements.

-

Customization: We offer cutting, heat treatment, and surface finishing services to ensure our steel meets your exact specifications.

-

Quality Assurance: Every product undergoes strict quality testing, ensuring superior performance and durability.

-

Global Reach: With experience supplying top-quality steel globally, we provide reliable materials for demanding applications.

❓ FAQ: Common Questions About Steel Similar to 4140

Q1: What is the main difference between 4140 steel and 4340 steel?

A1: The main difference is that 4340 steel contains higher nickel content, which enhances toughness and fatigue resistance, making it ideal for more demanding applications like aerospace.

Q2: Is 4130 steel a good substitute for 4140 steel?

A2: 4130 steel is a lower-strength alternative, but it offers better weldability and is more cost-effective, making it ideal for lighter-duty applications.

Q3: Can 8620 steel be used for applications requiring high wear resistance?

A3: Yes, 8620 steel offers excellent case-hardening properties, making it a great choice for gears and shafts that need to withstand wear without sacrificing toughness.