What Type of Steel is 4140 – A Tough Alloy with Endless Potential

What Type of Steel is 4140 – A Tough Alloy with Endless Potential

When it comes to choosing a versatile and high-strength steel, what type of steel is 4140 often comes up as a top candidate. Known for its excellent mechanical properties, toughness, and wear resistance, 4140 steel is widely used in industries ranging from automotive to oil and gas. But what exactly is 4140 steel? What kind of steel family does it belong to? And how does it perform under heat, pressure, or stress?

Let’s dive deep into the world of 4140 steel and answer all your burning questions in this in-depth guide! 🔍

✨ What Kind of Steel Is 4140?

4140 steel is a chromium-molybdenum alloy steel that belongs to the low alloy steel family. It’s often classified as medium-carbon steel due to its carbon content of approximately 0.38% to 0.43%. It offers a unique balance between strength, hardness, and ductility—making it an ideal material for components that require high fatigue resistance and impact strength.

It is commonly designated by the SAE/AISI classification system. In this system:

-

“41” stands for chromium-molybdenum steels

-

“40” represents the carbon content (0.40%)

Other designations and 4140 steel specifications include:

-

AISI 4140

-

UNS G41400

-

DIN 1.7225

-

EN 42CrMo4

🔬 Chemical Composition of 4140 Steel

Here’s a breakdown of the typical chemical composition of 4140 alloy steel:

| Element | Content (%) |

|---|---|

| Carbon (C) | 0.38 – 0.43 |

| Chromium (Cr) | 0.80 – 1.10 |

| Manganese (Mn) | 0.75 – 1.00 |

| Molybdenum (Mo) | 0.15 – 0.25 |

| Silicon (Si) | 0.15 – 0.30 |

| Sulfur (S) | ≤ 0.040 |

| Phosphorus (P) | ≤ 0.035 |

This composition gives 4140 its excellent tensile strength and wear resistance.

⚙️ Mechanical Properties of 4140 Steel

One of the reasons what type of steel is 4140 is such a common query is due to its impressive mechanical performance. Here are the typical properties in its normalized condition:

| Property | Value |

|---|---|

| Tensile Strength | 850–1000 MPa (123–145 ksi) |

| Yield Strength | 650–800 MPa (94–116 ksi) |

| Elongation | 20–25% |

| Hardness (HB) | 197–235 Brinell (normalized) |

| Modulus of Elasticity | ~205 GPa |

| Impact Toughness | Good at moderate temperatures |

These properties can be further enhanced by heat treatments like quenching and tempering, which is why 4140 is often used in high-stress machine parts.

🧪 Is 4140 Hot or Cold Rolled?

Both hot-rolled and cold-drawn forms are available, but hot-rolled 4140 is more common in plate or bar stock. Cold drawing is typically used for applications that require tighter tolerances and a smoother surface finish.

So, if you’re wondering is 4140 steel hot or cold rolled, the answer is—both, depending on the application!

🔩 Common Applications of 4140 Steel

Because of its excellent combination of strength and toughness, 4140 steel is a go-to material in several demanding industries.

| Industry | Typical Applications |

|---|---|

| Automotive | Crankshafts, axles, gears |

| Oil & Gas | Drill collars, wellhead equipment |

| Tooling | Dies, jigs, and fixtures |

| Machinery | Shafts, couplings, spindles |

| Aerospace | Structural parts, landing gear components |

Thanks to its outstanding fatigue strength, 4140 steel for tool making and 4140 steel for structural components are two commonly discussed long-tail applications.

🔧 Is 4140 Steel Weldable?

Yes, but with precautions. 4140 steel has higher hardenability, which means it can form brittle martensite if not welded properly. Preheating to around 315–400°C and post-weld stress relief are highly recommended. This is especially important in applications like preheat for welding 4140 steel and stress relieving 4140 steel after welding to avoid cracking.

🧠 Why Engineers Love 4140

Engineers often select 4140 because it checks all the right boxes:

-

High strength-to-weight ratio

-

Great wear resistance

-

Decent machinability (with the right tools and speeds)

-

Heat treatable to a wide range of hardness values

In fact, how strong is 4140 steel is a common engineering question—and the answer is: very strong when treated right!

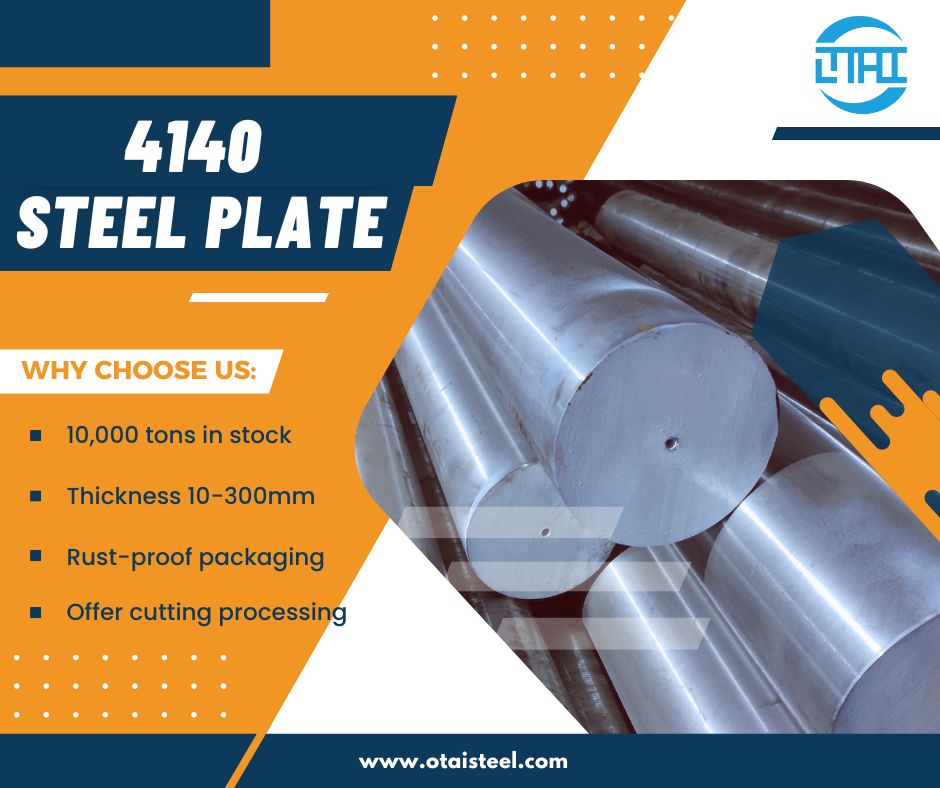

🏆Why Choose Otai Special Steel?

At Otai Special Steel, we specialize in supplying high-quality 4140 steel in various forms—flat bar, round bar, and plates—with thicknesses ranging from 6mm to 300mm. Here’s what sets us apart:

- Over 10,000 tons of stock ready for delivery

- Customized cutting and heat treatment services

- Ultrasonic testing (UT), hardness testing, and composition analysis

- Experience serving top-tier clients like Thyssenkrupp and Schlumberger

- Competitive pricing with fast, responsive customer service

Whether you’re sourcing 4140 steel for shafts, molds, or structural parts, we’ve got you covered.

📞 Contact us today for an instant quote or technical support!

📧 Contact us: jack@otaisteel.com

📱 WhatsApp: +8676923190193

❓ FAQ: What People Also Ask

Q1: Is 4140 steel the same as chromoly?

A: Yes, 4140 is a type of chromoly steel (chromium-molybdenum alloy). It’s a medium-carbon steel with enhanced strength and toughness.

Q2: Can 4140 steel be hardened?

A: Absolutely! Through quenching and tempering, 4140 can achieve hardness levels up to 60 HRC.

Q3: Is 4140 better than 1045 steel?

A: It depends on the application. 4140 offers higher strength and wear resistance, while 1045 is easier to machine.

Q4: What is the difference between 4140 and 4130 steel?

A: 4140 has higher carbon content, which means greater strength and hardness compared to 4130.

Q5: Is 4140 suitable for making knives?

A: It’s not commonly used for knives because it’s harder to sharpen than tool steels like D2 or O1. But it is tough and can be used in impact tools.