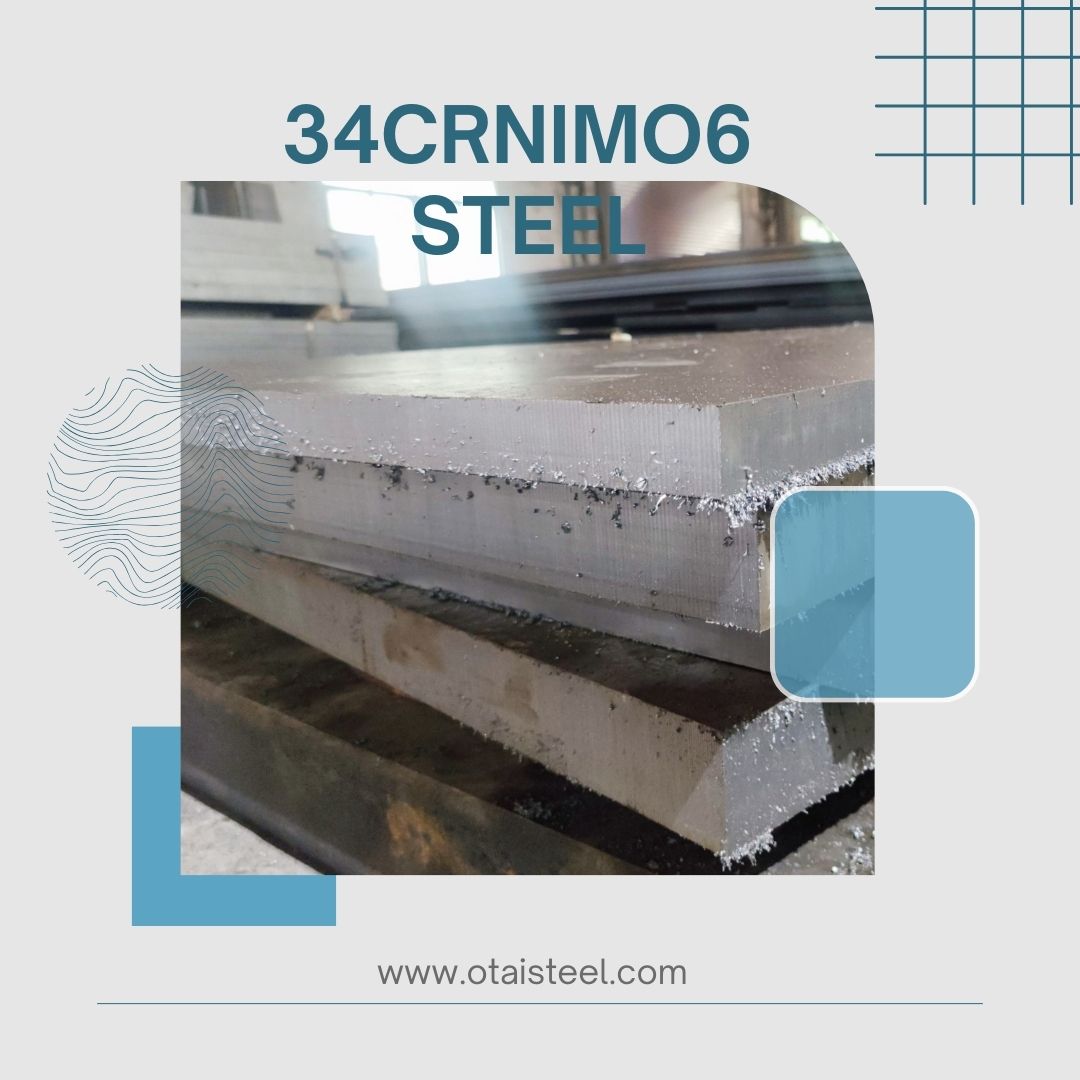

34CrNiMo6 is a high-strength steel alloy renowned for its exceptional properties, making it a preferred choice in various industries. In this article, we will explore the wide range of applications that benefit from the unique characteristics of 34CrNiMo6, highlighting its importance in modern engineering and manufacturing. (34crnimo6 application)

34CrNiMo6 is a high-strength steel alloy renowned for its exceptional properties, making it a preferred choice in various industries. In this article, we will explore the wide range of applications that benefit from the unique characteristics of 34CrNiMo6, highlighting its importance in modern engineering and manufacturing. (34crnimo6 application)

Powerful Performer in Gear Manufacturing

- 34CrNiMo6 is highly regarded for its use in gear manufacturing.

- Its superior tensile strength and toughness make it an ideal choice for gears that transmit heavy loads.

- The alloy’s wear resistance ensures long-lasting and reliable gear performance.

Critical Role in Shaft Production

- The exceptional combination of strength and toughness makes 34CrNiMo6 an excellent choice for producing shafts.

- It ensures that shafts can withstand high stress and bending moments.

- The alloy’s ability to maintain its properties under challenging conditions is crucial for shaft reliability.

Versatile Aerospace 34crnimo6 application

- Aerospace engineering relies on materials that offer high strength and fatigue resistance.

- 34CrNiMo6 is used in aerospace components, such as landing gear, where it meets stringent requirements for safety and performance.

- The alloy’s durability under extreme conditions makes it indispensable in this sector.

Heavy Machinery and Construction

- In construction and heavy machinery, 34CrNiMo6 is employed in critical components.

- Its high tensile strength and impact resistance ensure the safety and longevity of these machines.

- The alloy’s ability to endure heavy loads and extreme working conditions is invaluable.

Oil and Gas Exploration

- The oil and gas industry relies on materials that can withstand harsh environments.

- 34CrNiMo6 is used in components like drilling equipment.

- Its corrosion resistance and mechanical properties make it well-suited for the challenging conditions of oil and gas exploration.

Automotive Engineering

- 34CrNiMo6 plays a vital role in the automotive sector.

- It is used in critical parts like crankshafts, connecting rods, and gears.

- The alloy’s ability to enhance fuel efficiency and reduce emissions contributes to sustainability in the automotive industry.

Marine Engineering and Naval Applications

- In marine engineering, materials must withstand the corrosive effects of saltwater.

- 34CrNiMo6 is used in marine components such as propeller shafts.

- Its resistance to corrosion and durability in marine environments is crucial for naval operations.

Power Generation and Renewable Energy

- 34CrNiMo6 is employed in power generation equipment, such as wind turbine components.

- Its exceptional fatigue resistance ensures the reliability and longevity of renewable energy systems.

The applications of 34CrNiMo6 steel are diverse and essential in various industries, including manufacturing, aerospace, construction, automotive, marine engineering, and renewable energy. Its unique combination of strength, toughness, and resistance to corrosion and wear make it a top choice for applications where performance and durability are crucial.