In the world of metals and alloys, 4140 alloy steel round bar stands out as a versatile and robust material with a wide range of applications.

Understanding 4140 Alloy Steel

At its core, 4140 alloy steel is a chromium-molybdenum (chromoly) steel known for its exceptional strength and durability. Let’s delve deeper into its composition and key properties.

Composition:

- Chromium (Cr): Typically, 4140 steel contains around 0.8-1.1% chromium, which enhances its resistance to corrosion and wear. This makes it suitable for applications where exposure to harsh environments or chemicals is a concern.

- Molybdenum (Mo): The addition of 0.15-0.25% molybdenum improves the steel’s high-temperature strength and overall toughness. It’s a crucial element for applications involving elevated temperatures.

- Carbon (C): Carbon content in 4140 alloy steel ranges from 0.38% to 0.43%. This contributes to the steel’s hardness and strength.

- Other Elements: Depending on the specific grade and manufacturer, trace amounts of other elements like manganese (Mn), silicon (Si), and sulfur (S) may be present.

Key Properties:

- High Tensile Strength: 4140 alloy steel is renowned for its exceptional tensile strength, making it a top choice for structural components, gears, and other high-stress applications.

- Toughness: It offers good toughness, especially when properly heat-treated. This characteristic is invaluable in applications where resistance to impact and shock loading is crucial.

- Hardness: Through heat treatment processes, 4140 steel can achieve varying levels of hardness, typically in the range of 28-32 HRC (Rockwell Hardness Scale C).

- Machinability: While 4140 alloy steel can be machined, its hardness can pose challenges during machining. Proper tooling and techniques are essential for optimal results.

Applications of 4140 Alloy Steel Round Bar

4140 alloy steel’s versatile properties make it a material of choice across a wide spectrum of industries and applications. Let’s explore where this remarkable steel finds its footing:

- Aerospace: In the aerospace industry, 4140 steel is used for critical components such as landing gear parts, structural components, and engine components due to its high strength-to-weight ratio.

- Automotive: It’s a key player in automotive applications, including the manufacturing of gears, axles, crankshafts, and suspension components.

- Oil and Gas: 4140 alloy steel is employed in the oil and gas sector for drill collars, drilling tools, and other components that must withstand harsh drilling conditions.

- Construction: The construction industry utilizes 4140 steel for structural parts, such as heavy equipment components and crane shafts, where durability and strength are paramount.

- Machinery and Equipment: This steel is found in a wide range of machinery and equipment, from manufacturing machines to agricultural machinery, owing to its strength and wear resistance.

- Firearms: Some firearm manufacturers use 4140 alloy steel for gun barrels and critical firearm components due to its strength and ability to withstand high-pressure conditions.

- Tool and Die Making: 4140 steel is a preferred choice for tool and die making, particularly for forging dies, because it can maintain its hardness at elevated temperatures.

- Motorcycle and Bicycle Manufacturing: It’s utilized in the production of motorcycle and bicycle frames and components due to its strength and ability to withstand stress.

Heat Treatment and Hardening

Achieving the desired mechanical properties in 4140 alloy steel often involves heat treatment processes such as quenching and tempering. The heat treatment process helps fine-tune the steel’s hardness, toughness, and overall performance for specific applications.

Frequently Asked Questions (FAQs)

- Is 4140 alloy steel corrosion-resistant?

While 4140 steel contains chromium for improved corrosion resistance, it is not considered highly corrosion-resistant. It is advisable to apply appropriate coatings or protection in corrosive environments.

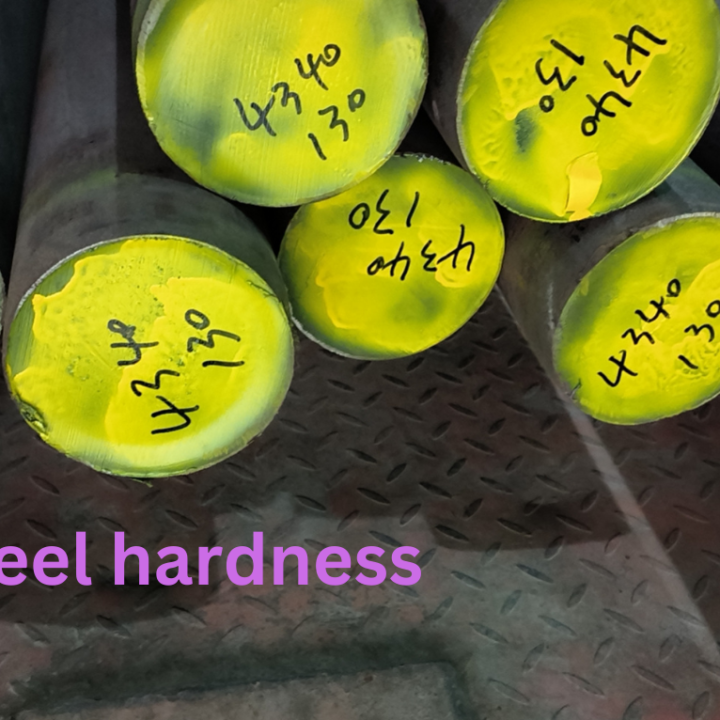

- What are the differences between 4140 and 4340 alloy steel?

4140 steel has a lower carbon content than 4340 steel, making it easier to machine. However, 4340 steel offers higher strength and toughness, particularly in larger cross-sections, and is often used for heavy-duty applications.

- Can 4140 alloy steel be welded?

Yes, 4140 steel can be welded using suitable welding techniques and precautions. However, post-weld heat treatment may be necessary to restore its properties, particularly in the heat-affected zone.

- What is the maximum hardness that can be achieved through heat treatment of 4140 steel?

Depending on the specific heat treatment process, 4140 steel can achieve a hardness of up to approximately 58-60 HRC.

- Is 4140 alloy steel round bar readily available in various sizes and shapes?

Yes, 4140 alloy steel round bars are available in a wide range of sizes and can also be obtained in different shapes, including square and flat bars, to suit various applications.