The Modeling and Simulation of 4140 Steel Behavior under Different Conditions

4140 steel has been studied under different conditions using modeling and simulation techniques. The thermo-viscoplastic behaviors of 4140 steel have been investigated over wide ranges of strain rate and deformation temperature by isothermal compression tests. Based on the experimental results, a unified viscoplastic constitutive model has been proposed to describe the hot compressive deformation behaviors of the studied steel.

A novel multiscale material plasticity simulation framework has been developed to predict the deformation behaviors of 4140 steel under various high-performance cutting conditions. The morphologies of dislocations at different physical simulation times. It is indicated that the dislocation density in the unit cell increased massively under a high strain rate. The high shear strain rate activated cross-slip on all possible slip systems of 4140 steel. (4140 Steel Behavior)

Mechanical structure-property relations have been quantified for 4140 steel under different strain rates and temperatures.

The structure-property relations were used to calibrate a microstructure-based internal state variable plasticity-damage model for monotonic tension. Including compression, and torsion plasticity, as well as damage evolution.

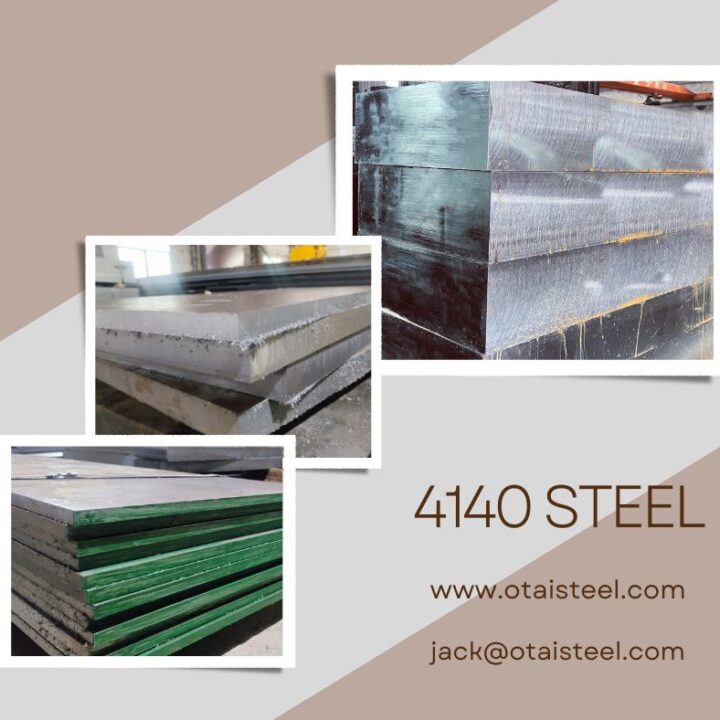

4140 steel is a fine-grained, low-alloy steel that offers an optimum heat-treat response in heavier cross-sections. It meets 4140 standards and has improved hardenability and strength in heavier cross-sections. It has many uses in the aerospace, oil and gas, and automotive industries. Typical uses are thin-walled pressure vessels, forged gears and shafts, and spindles (lathe spindles, milling …).