AISI 8620 Steel is a low alloy nickel, chromium, molybdenum case hardening steel, as a common, carburizing alloy steel, it is more responsive to mechanical and heat treatments than carbon steel. This alloy steel is flexible during hardening treatments, thus enabling improvement of case/core properties. Generally speaking, AISI 8620 steel is supplied in the rolled condition with a maximum hardness HB 255max. AISI steel 8620 offers high external strength and good internal strength, making it highly wear-resistant.

Chemical Composition

The following table shows the chemical composition of AISI 8620 alloy steel.

| Element | Content (%) |

| Iron, Fe | 96.895-98.02 |

| Manganese, Mn | 0.700-0.900 |

| Nickel, Ni | 0.400-0.700 |

| Chromium, Cr | 0.400-0.600 |

| Carbon, C | 0.180-0.230 |

| Silicon, Si | 0.150-0.350 |

| Molybdenum, Mo | 0.150-0.250 |

| Sulfur, S | ≤ 0.0400 |

| Phosphorous, P | ≤ 0.0350 |

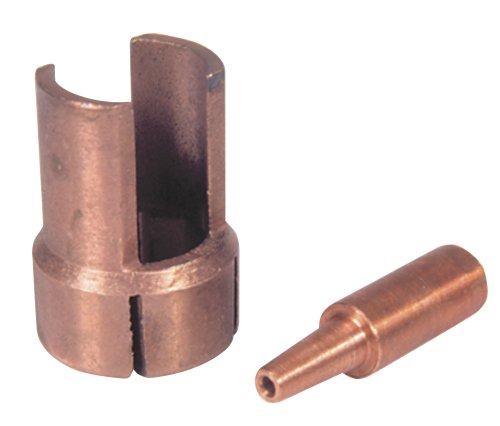

AISI 8620 Steel is suited for applications that require a combination of toughness and wear resistance. AISI 8620 steel material is used extensively by all industry sectors, for example, manufacturing the engine of the tractor and the small –and medium-sized vehicles.

Typical applications are: Arbors, Bearings, Bushings, Cam Shafts, Differential Pinions, Guide Pins, King Pins, Pistons Pins, Gears, Splined Shafts, Ratchets, Sleeves .because the 8620 steel contains Molybdenum, so it shows good combination properties and heat resistance. One of our clients from Malaysia imported our 8620 steel in order to make the gear of the automobile.

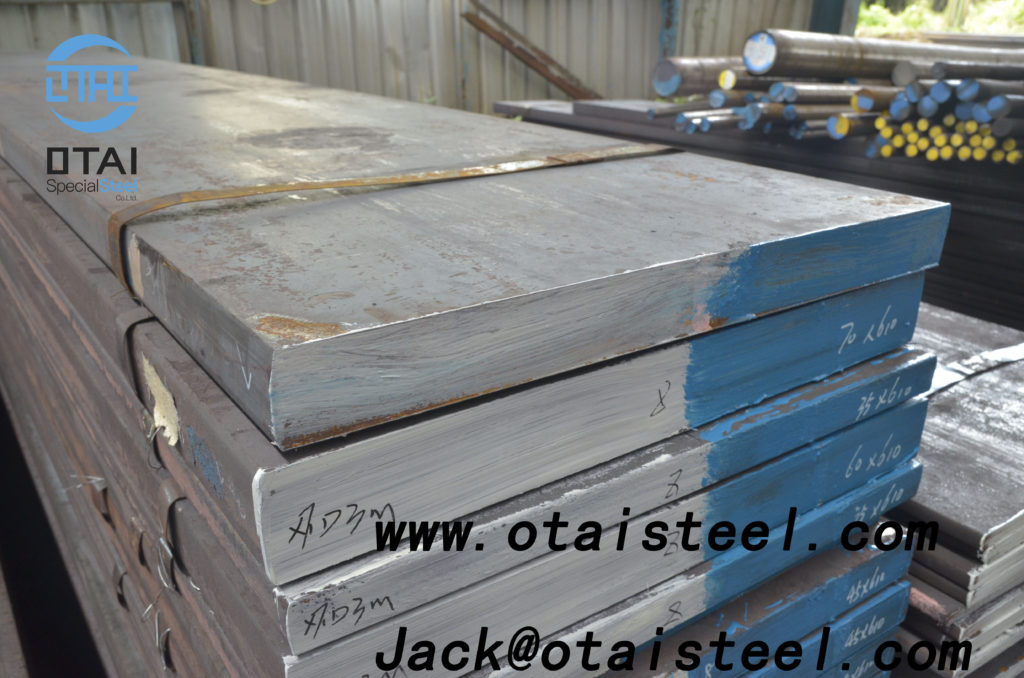

Dongguan Otai Special Steel Co Ltd Based on the industrial City of Dongguan, in Guangdong Province, China, our premises are 8000m2 and have the capacity to store/produce 2000 tons of steel at any one time. We expand our market worldwide, we expect you to join us .we are proud of our powerful, modern machinery. Precision engineering – our 20 years experience in the steel industry means the quality we provide is world-class and Otai Steel becomes one comprehensive special steel factory, stockist, and exporter. Welcome to request a quote.

In this new social environment, the Chinese steel industry in the process of foreign trade, to the actual situation and the basic status quo in the industry to analyze and judge. in the process of export trade, it can easily meet the challenges and difficulties in the international environment. At the same time according to the domestic market situation of policy changes and restructuring, it is needed to improve the trade environment.

In this new social environment, the Chinese steel industry in the process of foreign trade, to the actual situation and the basic status quo in the industry to analyze and judge. in the process of export trade, it can easily meet the challenges and difficulties in the international environment. At the same time according to the domestic market situation of policy changes and restructuring, it is needed to improve the trade environment.

COMPOSITION

COMPOSITION