All year round, Otai can guarantee our 42crmo4 steel plates stocks is more than 800 tons. We can support small-batch wholesale, various and complete specifications with the immediate delivery arrangement after placing an order. Otai Special Steel has a large stock of steel plates at competitive prices throughout the year. Otai ’s steel keeps various and complete specifications and speedy delivery.

For the purchase of 42CrMO4 Steel plates, foreign buyers often complain about the high price of small quantity from suppliers. Most of the domestic suppliers are not direct manufacturers, need to transfer goods from other suppliers, midway through many hands, so that the product price is very high. But for us, Otai, we are the direct manufacturers to cut out the middlemen and our prices are very competitive.

Customer’s story

Let me share with you a real case of one of our clients. Louis from Argentina send us an inquiry about the 42Crmo4 Steel plates, which required a lot of specifications and a small quantity. Louis asked many suppliers who were unwilling to cooperate and finally found us. We are the source manufacturer so that we can meet the needs of customers to customize the specifications of goods. The customer placed the order successfully. After receiving the goods, the customer said that he would seek our cooperation for a long time.

Otai 42Crmo4 Steel plates, 2 hours after-sale response, 2 days earlier than expected.

In solar power generation, steel is used not only as a frame to support solar panels but also as a framework for transformers and transmission infrastructure. In tidal power generation, steel is used as an armature core for generators, steel piles for supporting power turbines, and a nacelle casing for use as a generator assembly and power plant infrastructure. The geothermal heat pump, a device for collecting geothermal energy, is made of steel. As power generation companies continue to improve their production technologies, they will further reduce the cost of generating electricity such as wind power and photovoltaics, and achieve a virtuous cycle. The rapid development of renewable energy such as wind power and photovoltaics in the future will drive the demand for steel for renewable energy engineering equipment.

In solar power generation, steel is used not only as a frame to support solar panels but also as a framework for transformers and transmission infrastructure. In tidal power generation, steel is used as an armature core for generators, steel piles for supporting power turbines, and a nacelle casing for use as a generator assembly and power plant infrastructure. The geothermal heat pump, a device for collecting geothermal energy, is made of steel. As power generation companies continue to improve their production technologies, they will further reduce the cost of generating electricity such as wind power and photovoltaics, and achieve a virtuous cycle. The rapid development of renewable energy such as wind power and photovoltaics in the future will drive the demand for steel for renewable energy engineering equipment. Chemical Composition Comparison: 4340 vs 4140 steel

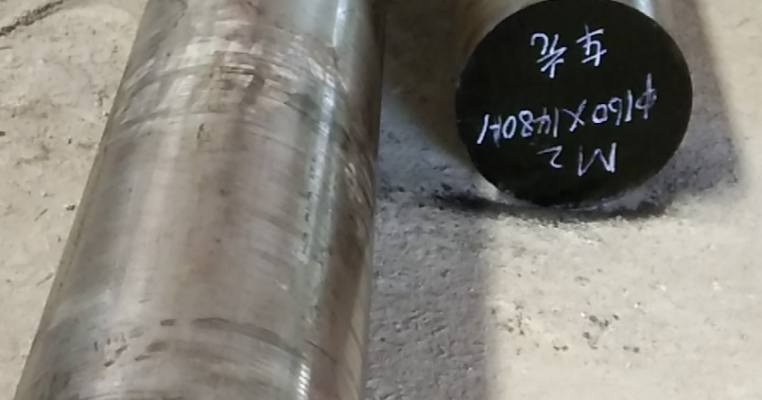

Chemical Composition Comparison: 4340 vs 4140 steel Hot Work Tool Steel:

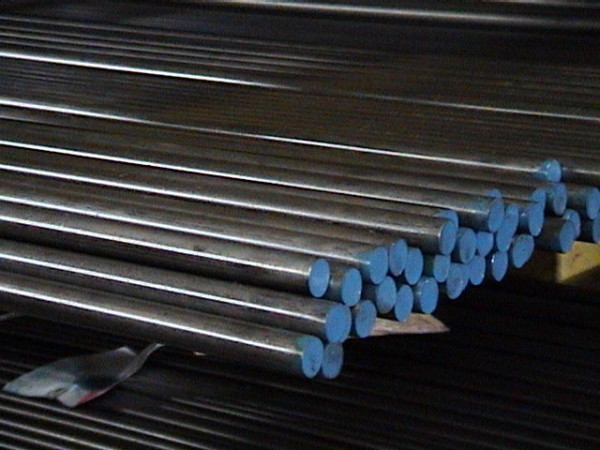

Hot Work Tool Steel: 1.Carbon steel

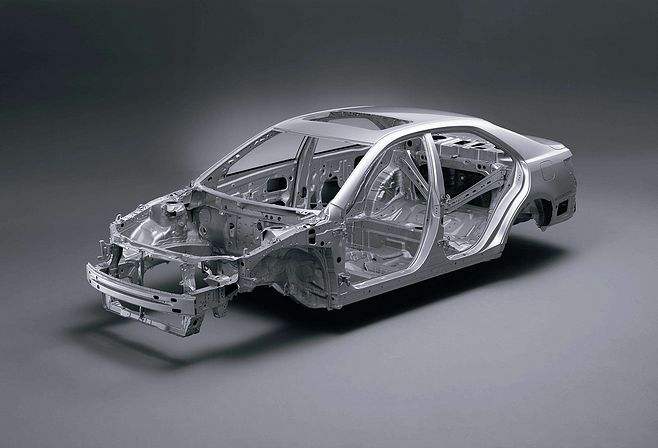

1.Carbon steel The body-in-white is made up of several sheets of steel joined together by welding. However, the steel used in the entire body is a low alloy steel. The biggest advantage of low alloy steel is that it has good processing performance and the steel itself has high mechanical strength. At the same time, low-alloy steel has better corrosion resistance than ordinary steel. In the natural environment, a layer of brown and dense oxide layer will be formed on the surface of low-alloy steel. This layer of oxide is a good way to isolate the internal steel from the outside air. , better play a role in rust prevention.

The body-in-white is made up of several sheets of steel joined together by welding. However, the steel used in the entire body is a low alloy steel. The biggest advantage of low alloy steel is that it has good processing performance and the steel itself has high mechanical strength. At the same time, low-alloy steel has better corrosion resistance than ordinary steel. In the natural environment, a layer of brown and dense oxide layer will be formed on the surface of low-alloy steel. This layer of oxide is a good way to isolate the internal steel from the outside air. , better play a role in rust prevention.