Understanding the Properties of 4140 Steel Plate: A Guide for Engineers

4140 plate is a popular alloy steel. Because of its high strength, toughness, and wear resistance, it is widely used in various industrial applications. The following can help engineers understand the performance of the 4140 steel plate:

Chemical composition

4140 steel plate contains chromium, molybdenum, and manganese, giving it unique properties. Chromium and molybdenum increase their hardness and strength. Manganese enhances its ductility and toughness.

Heat treatment

4140 steel plate can be heat treated according to the specific application to obtain different properties. The most common heat treatment methods are quenching and tempering. It involves heating the material to a specific temperature and then cooling it quickly to reach the desired level of hardness. Finally, temper to improve toughness.

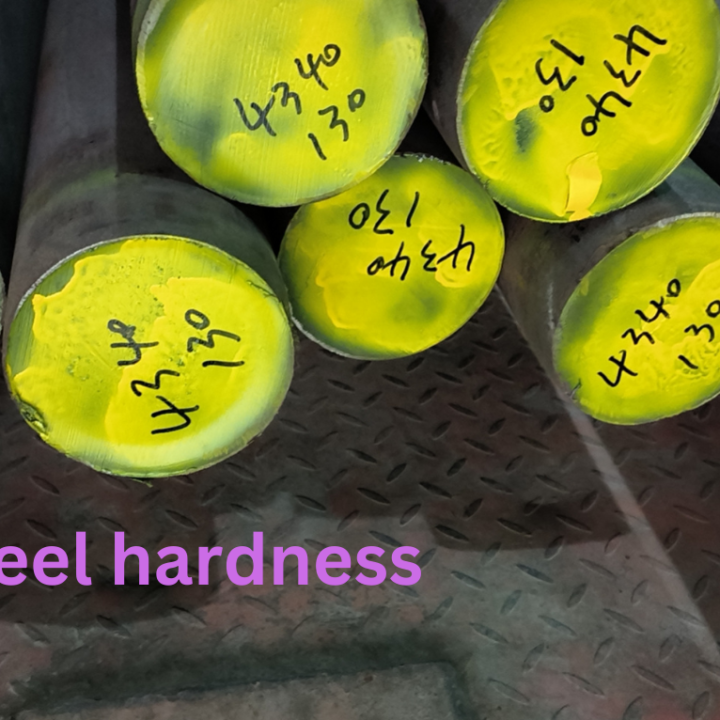

Hardness

Depending on the application, the 4140 steel plate can be hardened to a certain range of hardness levels. It can be heat treated to reach a hardness of up to 60 HRC. Make it suitable for cutting tools and other high-wear applications.

Strength

4140 steel plate has high tensile strength, which means it can withstand heavy loads and stresses without breaking. Its strength is particularly useful in applications such as gears, shafts, and structural components.

Toughness

4140 steel plate has good toughness and can withstand bending and twisting without breaking. This makes it suitable for applications where impact or cyclic loads are present.

Corrosion resistance

Although the 4140 steel plate has good atmospheric corrosion resistance, it is not suitable for use in harsh environments such as the ocean or acidic environments. In these cases, additional surface treatments or coatings may be required to prevent corrosion.

Weldability

4140 steel plate can be welded by arc welding, MIG welding, TIG welding, and other standard welding technology. However, it is important to follow proper welding procedures and use appropriate pre – and post-welding heat treatments to prevent cracking and ensure good mechanical properties.

Machinability

4140 steel plates can be machined, but require careful machining to achieve a good surface finish and dimensional accuracy. It has a tendency to work hard in the process of machining, which will affect the tool life and cause surface deformation.

Fatigue resistance

4140 steel plate has good fatigue resistance. This means it can withstand repeated loading and unloading without cracking or breaking. This makes it suitable for applications where cyclic loads are present. Examples include rotating machinery or structural parts that are subjected to wind or vibration.

4140 plate is a versatile and reliable alloy steel. Its series of mechanical properties make it suitable for various industrial applications. By understanding their properties and how to operate them through heat treatment, engineers can select the right materials for their specific needs and ensure the success of the project. (the Properties of 4140 Steel Plate)